3-D printing lightweight, flexible multiple materials in real time, including electronic circuits

September 22, 2015

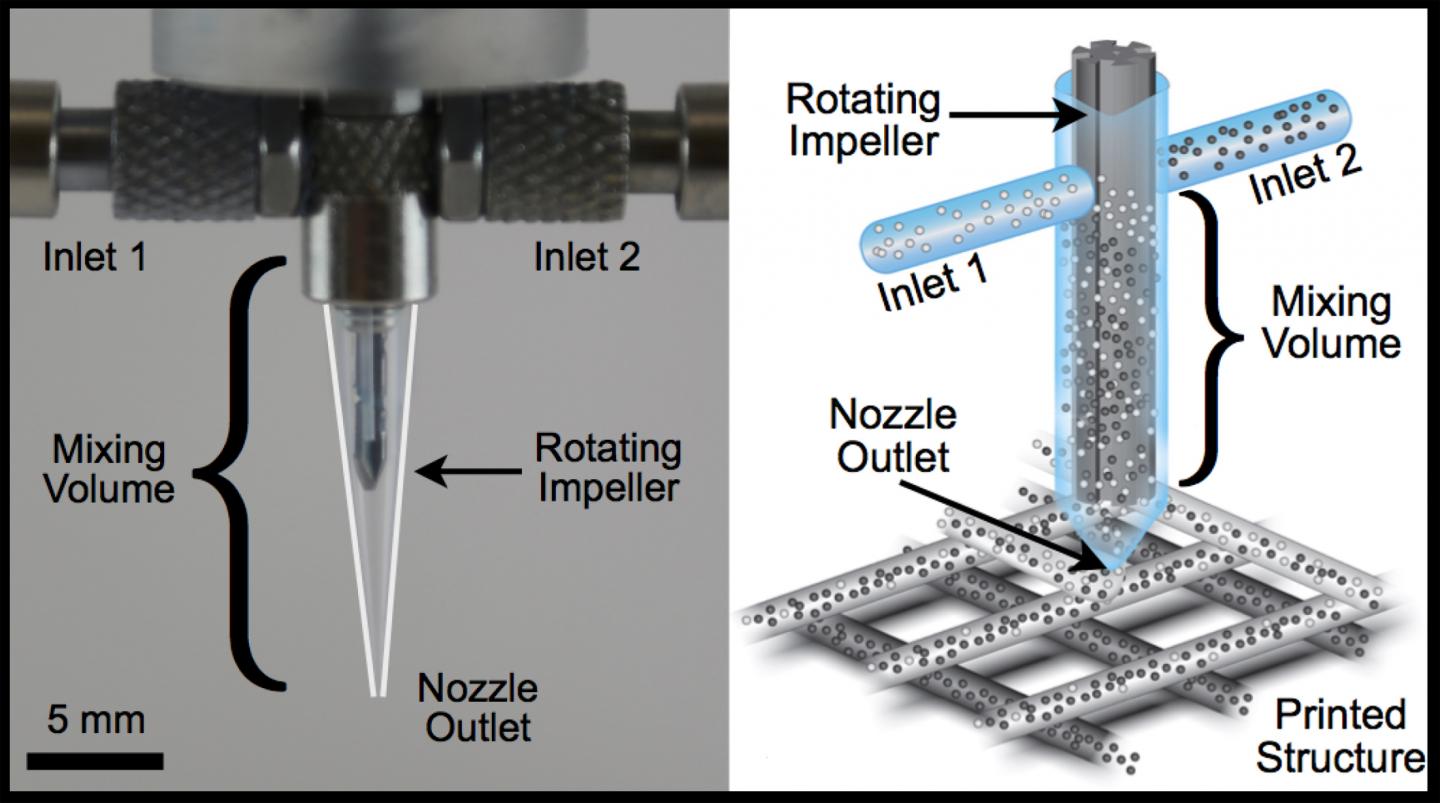

Multiple-materials printer. Each fluid enters the mixing chamber through a separate inlet and is mixed in a narrow gap by an impeller rotating at a constant rate. Optical image (left) and schematic illustration (right) of impeller-based mixing nozzle. (credit: Thomas Ober, Harvard SEAS/Wyss Institute)

Harvard researchers have designed new printheads for 3-D printers that can simultaneously handle multiple materials with different properties, allowing for 3-D printing wearable devices, flexible electronics, and soft robots.

To print a flexible device, including the electronics, a 3-D printer must be able to seamlessly transition from a flexible material that moves with the wearer’s joints for wearable applications, to a rigid material that accommodates the electronic components. It would also need to be able to embed electrical circuitry using multiple inks of varying conductivity and resistivity, and precisely switching between them while changing composition and geometry. And do it all in real time.

How this will change 3-D printing

The researchers say they have designed a new multimaterial printhead that do all of the above. It can handle a wide range of complex fluids by using a rotating impeller inside a microscale nozzle, seamlessly printing combinations of materials and processes that were not formerly possible:

- Mixed conductive and resistive inks to embed electrical circuitry inside 3D printed objects.

- Multiple inks within a single nozzle, eliminating the structural defects that often occur during the start-and-stop process of switching materials.

- Silicone elastomers, with gradient architectures composed of soft and rigid regions.

- Reactive materials, such as two-part epoxies, which typically harden quickly when the two parts are combined (think: Krazy glue).

The research was led by Jennifer A. Lewis, the Hansjörg Wyss Professor of Biologically Inspired Engineering at the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) and a Core Faculty Member at the Wyss Institute for Biologically Inspired Engineering at Harvard. The work was published in an open-access paper in Proceedings of the National Academy of Sciences (PNAS). It was supported by the Department of Energy Energy Frontier Research Center on Light-Material Interactions in Energy Conversion, the Intelligence Community Postdoctoral Fellowship program, and the Society in Science Branco-Weiss Foundation.

“The recent work by the Lewis Group is a significant advancement to the field of additive manufacturing,” said Christopher Spadaccini, Director of the Center for Engineered Materials, Manufacturing and Optimization at Lawrence Livermore National Lab. “By allowing for the mixing of two highly viscous materials on the fly, the promise of mixed material systems with disparate mechanical and functional properties becomes much more realistic. Before, this was really only a concept. This work will be foundational for applications which [require] integrated electrical and structural materials.”

Abstract of Active mixing of complex fluids at the microscale

Mixing of complex fluids at low Reynolds number is fundamental for a broad range of applications, including materials assembly, microfluidics, and biomedical devices. Of these materials, yield stress fluids (and gels) pose the most significant challenges, especially when they must be mixed in low volumes over short timescales. New scaling relationships between mixer dimensions and operating conditions are derived and experimentally verified to create a framework for designing active microfluidic mixers that can efficiently homogenize a wide range of complex fluids. Active mixing printheads are then designed and implemented for multimaterial 3D printing of viscoelastic inks with programmable control of local composition.