A 3D-printed Moon base baked from lunar dust

March 20, 2013

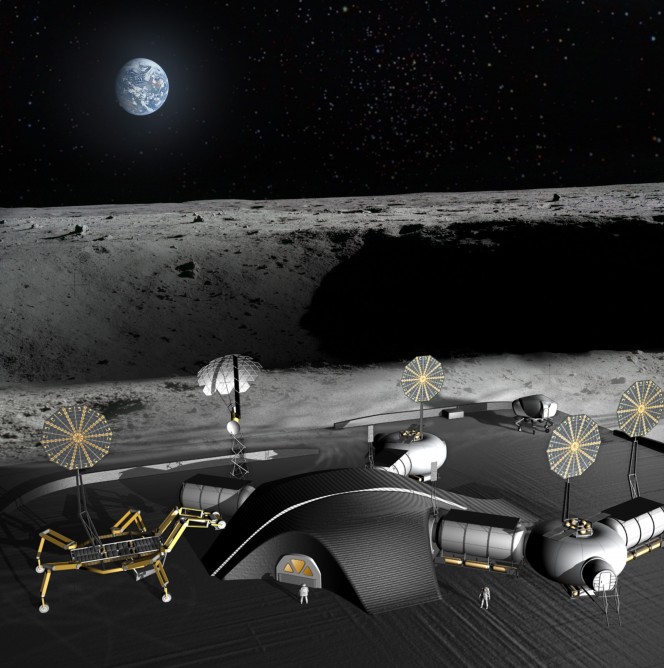

A possible lunar station near the Moon’s south pole (credit: SinterHab Design Team)

Space architects have unveiled a concept for a 3D-printed Moon base called SinterHab near the lunar south pole. Modules would be constructed from lunar dust by microwave sintering and contour crafting, built by a large NASA spider robot.

Unlike an earlier, more bulky concept using a mobile printing array of nozzles on a 6 meter frame to spray a binding solution (glue) onto a sand-like building material, the new concept uses microwave sintering to create a solid building material similar to ceramics — no glue requiired.

The iron nanoparticles in the lunar dust (produced by space weathering) make it possible to heat the dust up to 1200–1500 degrees C and melt it, even in a domestic microwave oven. When the lunar dust (regolith) is heated and the temperature is maintained below the melting point, particles bond together and the building blocks for the lunar habitat can be created.

In the future, we could build structures of entire cities on the surface of the Moon by using solar energy, the designers suggest. We can significantly decrease mass, costs and environmental impact if we don’t need to send glue or other binding agents from Earth. Furthermore, the hardening of the surrounding surface of the base would help mitigate the hazards of contamination from lunar dust, which is highly abrasive and harmful to both astronauts and equipment.

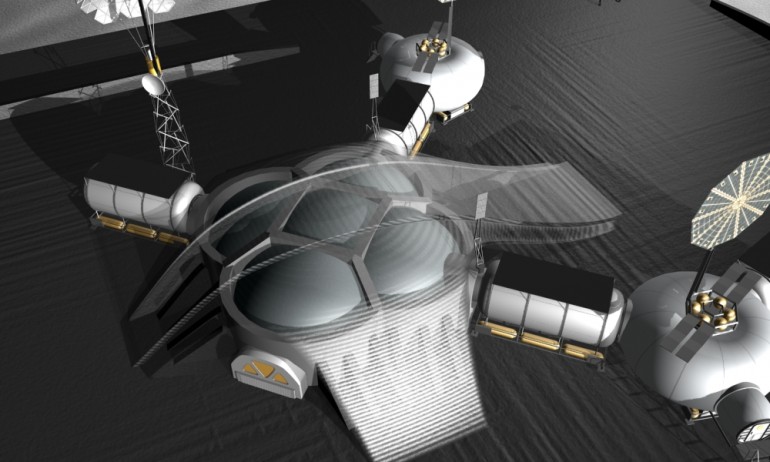

The radiation shielding is provided by the regolith structure, polymer layers of inflatable membrane, and water tanks in critical places.

The SinterHab designers claim there would be enough space inside the domes to cultivate gardens as part of a bio-regenerative life support system (credit: SinterHab Design Team)

Project SinterHab was initiated in 2009 at International Space University by space architects Tomas Rousek, Katarina Eriksson and Dr. Ondrej Doule in collaboration with Richard Rieber from NASA JPL.