A 3D printer to turn waste plastic into composting toilets, rainwater harvesting systems

November 27, 2012

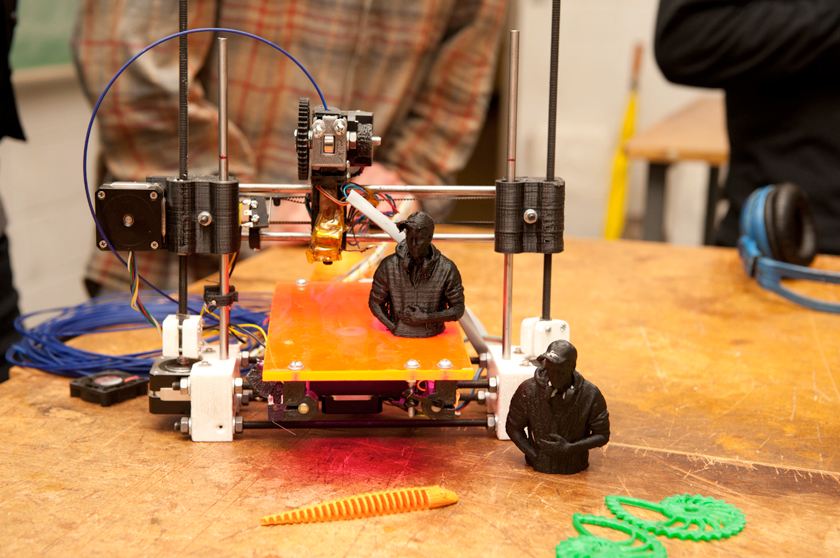

3-D printers work like inkjet printers but create 3-dimensional objects, one layer at a time. This smaller machine printed a likeness of undergraduate Brandon Bowman, whose body was scanned using a Kinect. (Credit: Alison Deng, UW Photography)

A University of Washington team claimed a $100,000 prize in the first 3D4D Challenge, an international contest to use 3-D printing for social benefit in the developing world.

The three undergraduates won to form a company that will work with partners in Oaxaca, Mexico.

Matthew Rogge, a mechanical engineering grad student, proposed to use giant 3-D printers to create composting latrines that are lightweight and use less energy to manufacture than concrete toilets.

The machine would also make rainwater catchment components that are specifically designed to fit to rain barrels, unlike current systems where joining available plumbing parts cause leaks and frequent failures.

Judges also were impressed by research the students conducted to prove their concept. In July the students printed a boat from more than 250 milk jugs and then entered it in a Seattle race. That proved they could create objects from recycled plastic and was a test run for their custom-built giant printer, also built from salvaged parts.

“With small-scale printers, the extruders can clog easily,” said Brandon Bowman, who also attended the competition. The huge printer that the students built, named “Big Red,” can not only create larger objects, but it also allows them to print with materials that are not perfectly clean.