A graphene-based light sensor 1,000 times more sensitive than current sensors

June 3, 2013

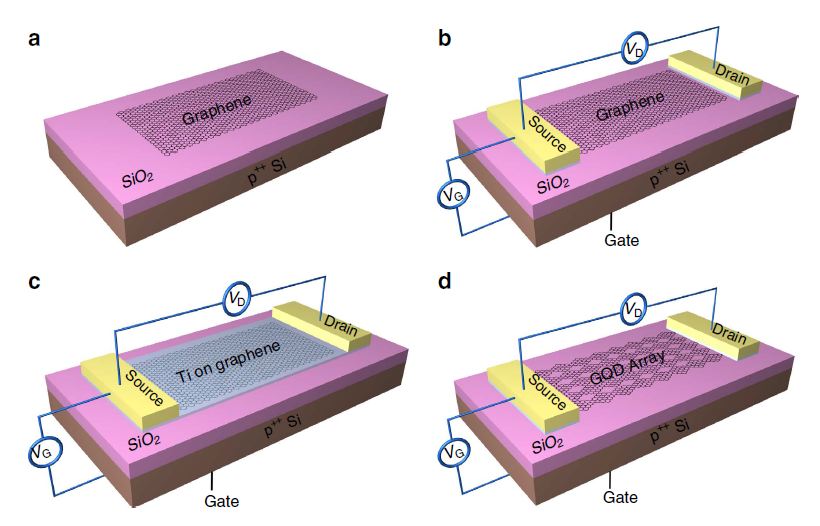

Fabrication process of the device. (a) A monolayer graphene was mechanically exfoliated onto a 285nm SiO2/Si substrate. (b) The graphene photodetector was processed into a FET structure. Two electrodes (that is, the source and the drain terminals) of Ti/Au (20 nm/80 nm) were fabricated on the graphene by photolithography and lift-off processes. The gate terminal was fabricated on the bottom of the Si substrate. (c) A thin nm-scale Ti sacrificial layer was deposited onto the graphene by electron-beam evaporation. (d) The Ti sacrificial layer was removed via wet etching, and then GQD array structure with various quantum dot (QD) sizes can be formed on the Si substrate depending on the thickness of the Ti layer. (Credit: Y. Z. Zhang et al./Nature Communications)

A new graphene-based image sensor invented at Nanyang Technological University (NTU) in Singapore is 1,000 times more sensitive to light than current imaging sensors found in today’s cameras and uses 10 times less energy because it operates at lower voltages, according to researchers.

The new nanoscale sensor is also believed to be the first to be able to detect a broad spectrum of light, from the visible to mid-infrared, with high photo response or sensitivity.

That means it is suitable for use in all types of cameras, including consumer, near- or mid-infrared cameras, traffic speed cameras, and satellite imaging.

When mass-produced, graphene sensors are also estimated to cost at least five times cheaper, the researchers say.

The sensor uses graphene materials, which are only one atom thick, and made of pure carbon atoms arranged in a honeycomb structure. Graphene has high electrical conductivity, among other properties, such as durability and flexibility.

The inventor of the graphene sensor, Assistant Professor Wang Qijie, from NTU’s School of Electrical & Electronic Engineering, said this is the first time that a broad-spectrum, highly photosensitive sensor has been developed using pure graphene.

“We have shown that it is now possible to create cheap, sensitive, and flexible photo sensors from graphene alone,” he said. “We expect our innovation will have great impact not only on the consumer imaging industry, but also in satellite imaging and communication industries, as well as the mid-infrared applications,” said Wang, who also holds a joint appointment in NTU’s School of Physical and Mathematical Sciences.

“While designing this sensor, we have kept current manufacturing practices in mind. This means the industry can in principle continue producing camera sensors using the CMOS (complementary metal-oxide-semiconductor) process, which is the prevailing technology used by the majority of factories in the electronics industry. Therefore manufacturers can easily replace the current base material of photo sensors with our new nano-structured graphene material.”

Wang expects that if adopted by industry, the cost of manufacturing imaging sensors would fall, eventually leading to cheaper cameras with longer battery life.

How the Graphene nanostructure works

Wang came up with an innovative idea to create nanostructures on graphene that will “trap” light-generated electron particles for a much longer time, resulting in a much stronger electric signal that then be processed into an image.

Trapping electrons is the key to achieving high photo-response in graphene, which makes it far more effective than the normal CMOS or CCD (charge-coupled device) image sensors, said Wang. The stronger the electric signals generated, the clearer and sharper the photos.

The next step is to work with industry collaborators to develop the graphene sensor into a commercial product.

The research is funded by the Nanyang Assistant Professorship start-up grant and supported partially by the Ministry of Education Tier 2 and 3 research grants.

UPDATE June 4, 2013: Nanyang Technological University is in Singapore, not South Korea.