A new 3-D printing method for creating patient-specific medical devices

November 4, 2015

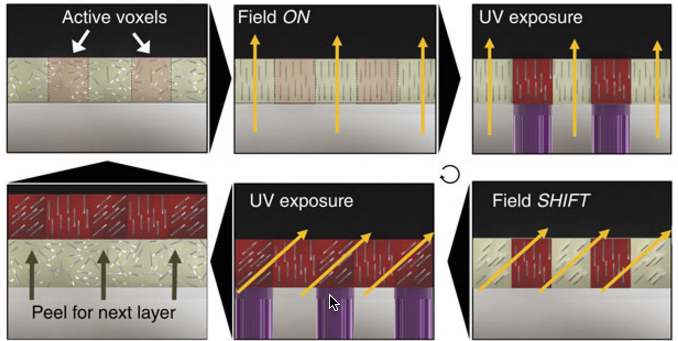

The 3D magnetic printing process systematically aligns and selectively polymerizes groupings of voxels (volume “pixels”) programmed to have specific reinforcement orientation within each layer of printed material based upon a shifting field. The 3-D printer build plate peels after a layer is complete to print additional layers. (credit: Joshua J. Martin et al./Nature Communications)

Northeastern University engineers have developed a 3-D printing process that uses magnetic fields to shape composite materials (mixes of plastics and ceramics) into patient-specific biomedical devices, such as catheters.

The devices are intended to be stronger and lighter than current models and the customized design could ensure an appropriate fit, said Randall Erb, assistant professor in the Department of Mechanical and Industrial Engineering.

The magnetic field enables the engineers to control how the ceramic fibers are arranged, allowing for control of the mechanical properties of the material. That control is critical if you’re crafting devices with complex architectures, such as customized miniature biomedical devices. Within a single patient-specific device, the corners, the curves, and the holes must all be reinforced by ceramic fibers arranged in just the right configuration to make the device durable.

This is the strategy taken by many natural composites from bones to trees. Fibers of calcium phosphate, the mineral component of bone, are naturally oriented precisely around the holes for blood vessels to ensure the bone’s strength and stability to enable, say, your femur to withstand a daily jog.

Aligning fibers with magnets

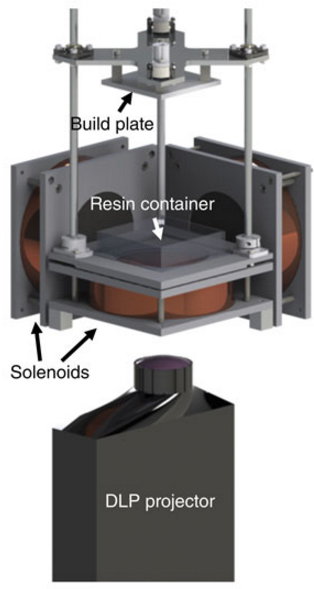

The 3D magnetic-printer setup. A digital light processor (DLP) photo-polymerizes resin with UV while a magnetic field is simultaneously applied via electromagnetic solenoids. (credit: Joshua J. Martin et al./Nature Communications)

Erb initially described the role of magnets in the composite-making process in a 2012 paper in the journal Science. First the researchers “magnetize” the ceramic fibers by dusting them very lightly with iron oxide, which has been FDA-approved for drug-delivery applications.

They then apply ultra-low magnetic fields to individual sections of the composite material — the ceramic fibers immersed in liquid plastic — to align the fibers according to the exacting specifications dictated by the product they are printing.

In a video accompanying the Science article, you can see the fibers spring to attention when the magnetic field is turned on. “Magnetic fields are very easy to apply,” says Erb. “They’re safe, and they penetrate not only our bodies but many other materials.”

Finally, in a process called “stereolithography,” they build the product, layer by layer, using a computer-controlled laser beam that hardens the plastic. Each six-by-six inch layer takes a minute to complete.

Using magnets, the new printing method aligns each minuscule fiber in the direction that conforms precisely to the geometry of the item being printed.

“If you can print a catheter whose geometry is specific to the individual patient, you can insert it up to a certain critical spot, you can avoid puncturing veins, and you can expedite delivery of the contents.”

The engineers’ open-access paper on the new technology appears in the Oct. 23 issue of Nature Communications.

Custom-designing neonatal catheters

Erb has received a $225,000 Small Business Technology Transfer grant from the National Institutes of Health to develop neonatal catheters with a local company. “Another of our goals is to use calcium phosphate fibers and biocompatible plastics to design surgical implants.”

Neonatal preemie with catheters (credit: March of Dimes Foundation)

The new technology is especially valuable for premature babies (“preemies”) in neonatal care units, some weighing just a bit over a pound, with plastic tubes snaking through their nose or mouth, or disappearing into veins or other parts of the body. Those tubes, or “catheters,” are how the babies get the necessary oxygen, nutrients, fluid, and medications to stay alive.

The problem is, today’s catheters only come in standard sizes and shapes, which means they cannot accommodate the needs of all premature babies. “With neonatal care, each baby is a different size, each baby has a different set of problems,” says Erb.

Worldwide, “15 million babies are born too soon every year” and of those, “1 million children die each year due to complications of preterm birth,” according to a report by the World Health Organization. This data was cited in the “March of Dimes Premature Birth Report Card,” issued today (Nov. 5) by March of Dimes. “Babies who survive an early birth often face serious and lifelong health problems, including breathing problems, jaundice, vision loss, cerebral palsy, and intellectual delays,” the March of Dimes report noted.

The report provides rates and grades for major cities or counties in each U.S. state and Puerto Rico. It also provides preterm birth rates by race and ethnicity. The U.S. preterm birth rate ranks among the worst of high-resource countries, the March of Dimes says.

Abstract of Designing bioinspired composite reinforcement architectures via 3D magnetic printing

Discontinuous fibre composites represent a class of materials that are strong, lightweight and have remarkable fracture toughness. These advantages partially explain the abundance and variety of discontinuous fibre composites that have evolved in the natural world. Many natural structures out-perform the conventional synthetic counterparts due, in part, to the more elaborate reinforcement architectures that occur in natural composites. Here we present an additive manufacturing approach that combines real-time colloidal assembly with existing additive manufacturing technologies to create highly programmable discontinuous fibre composites. This technology, termed as ‘3D magnetic printing’, has enabled us to recreate complex bioinspired reinforcement architectures that deliver enhanced material performance compared with monolithic structures. Further, we demonstrate that we can now design and evolve elaborate reinforcement architectures that are not found in nature, demonstrating a high level of possible customization in discontinuous fibre composites with arbitrary geometries.