A transistor material intended to replace silicon by 2024

July 7, 2014

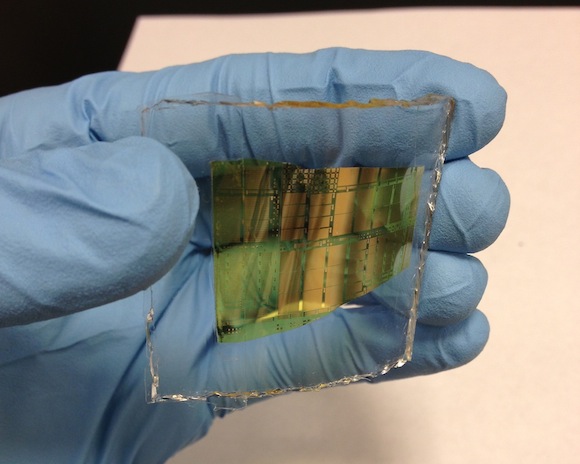

Hybrid CNT/IGZO circuits fabricated on a polyimide film laminated on a polydimethylsiloxane (PDMS) substrate (credit: USC Viterbi / Chongwu Zhou)

USC Viterbi School of Engineering researchers have developed a flexible, transparent, energy-efficient, lower-cost hybrid design that could replace silicon as the traditional transistor material used in electronic chips.

The new design, described in a paper recently published in Nature Communications, combines carbon nanotube thin-film transistors with thin-film transistors comprised of indium, gallium and zinc oxide (IGZO).

Electrical engineering professor Dr. Chongwu Zhou and USC Viterbi graduate students Haitian Chen, Yu Cao, and Jialu Zhang developed this energy-efficient circuit by integrating carbon nanotube (CNT) thin film transistors (TFT)

The inclusion of IGZO thin film transistors was necessary to provide power efficiency to increase battery life. If only carbon nanotubes had been used, the circuits would not be power-efficient.

“I came up with this concept in January 2013,” said Dr. Chongwu Zhou, professor in USC Viterbi’s Ming Hsieh Department of Electrical Engineering. “Before then, we were working hard to try to turn carbon nanotubes into n-type transistors and then one day, the idea came to me. Instead of working so hard to force nanotubes to do something that they are not good for, why don’t we just find another material which would be ideal for n-type transistors — in this case, IGZO — so we can achieve complementary circuits?”

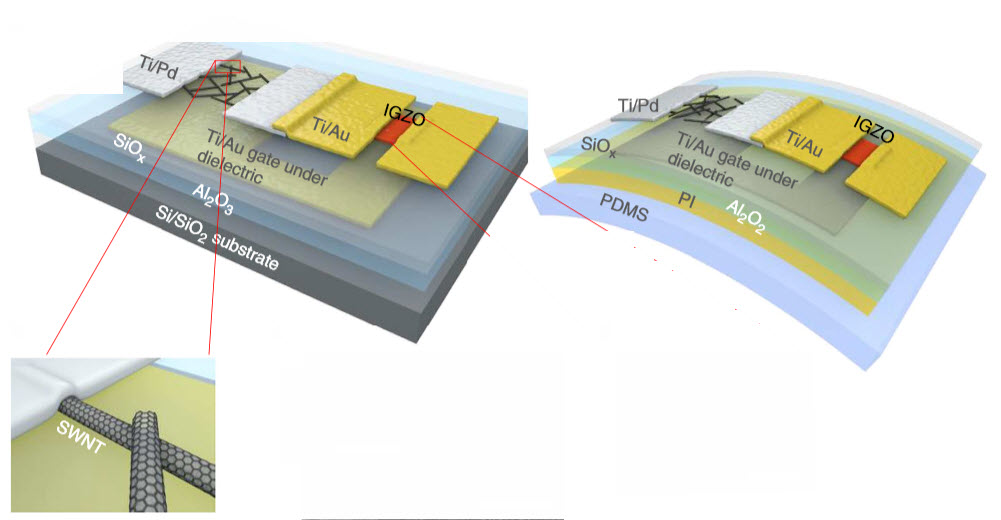

Three-dimensional schematic diagram of a CNT/IGZO complementary mode inverter on rigid substrate (left) and same circuit on flexible substrate (right) (credit: Haitian Chen et al./Nature Communications)

This hybridization of carbon nanotube thin films and IGZO thin films was achieved by combining their types, p-type and n-type, respectively, to create circuits that can operate complementarily, reducing power loss and increasing efficiency. By combining the two materials, their strengths have been joined and their weaknesses hidden.

Applications

The potential applications for this kind of integrated circuitry are numerous, including Organic Light Emitting Diodes (OLEDs), digital circuits, radio frequency identification (RFID) tags, sensors, wearable electronics, and flash memory devices. Even heads-up displays on vehicle windshields could soon be a reality.

The new technology also has major medical implications. Currently, memory used in computers and phones is made with silicon substrates, the surface on which memory chips are built. To obtain medical information from a patient such as heart rate or brainwave data, stiff electrode objects are placed on several fixed locations on the patient’s body. With this new hybridized circuit, however, electrodes could be placed all over the patient’s body, linked to a single large but flexible object.

With this development, Zhou and his team have circumvented the difficulty of creating n-type carbon nanotube TFTs and p-type IGZO TFTs by creating a hybrid integration of p-type carbon nanotube TFTs and n-type IGZO TFTs and demonstrating a large-scale integration of circuits. As a proof of concept, they achieved a scale ring oscillator consisting of over 1,000 transistors. Up to this point, all carbon nanotube-based transistors had a maximum number of 200 transistors.

“We believe this is a technological breakthrough, as no one has done this before,” said Haitian Chen, research assistant and electrical engineering PhD student at USC Viterbi. “This gives us further proof that we can make larger integrations so we can make more complicated circuits for computers and circuits.”

The next step for Zhou and his team will be to build more complicated circuits using a CNT and IGZO hybrid that achieves more complicated functions and computations, as well as to build circuits on flexible substrates.

“The possibilities are endless, as digital circuits can be used in any electronics,” Chen said. “One day we’ll be able to print these circuits as easily as newspapers.”

“We envisage that this technology may become sufficiently mature and be commercialized in ten years,” Chen told KurzweilAI in an email.

Abstract of Nature Communications paper

Carbon nanotubes and metal oxide semiconductors have emerged as important materials for p-type and n-type thin-film transistors, respectively; however, realizing sophisticated macroelectronics operating in complementary mode has been challenging due to the difficulty in making n-type carbon nanotube transistors and p-type metal oxide transistors. Here we report a hybrid integration of p-type carbon nanotube and n-type indium–gallium–zinc-oxide thin-film transistors to achieve large-scale (>1,000 transistors for 501-stage ring oscillators) complementary macroelectronic circuits on both rigid and flexible substrates. This approach of hybrid integration allows us to combine the strength of p-type carbon nanotube and n-type indium–gallium–zinc-oxide thin-film transistors, and offers high device yield and low device variation. Based on this approach, we report the successful demonstration of various logic gates (inverter, NAND and NOR gates), ring oscillators (from 51 stages to 501 stages) and dynamic logic circuits (dynamic inverter, NAND and NOR gates).