Antifreeze, cheap materials may lead to low-cost solar energy

July 5, 2013

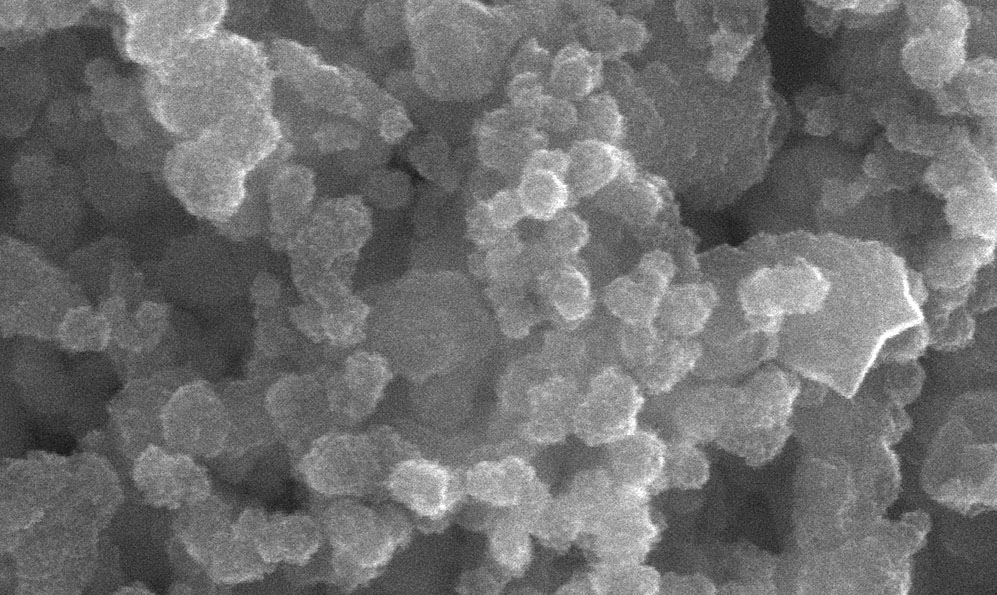

Solar-cell nanoparticles (credit: Oregon State University)

Engineers at Oregon State University have determined that ethylene glycol, commonly used in antifreeze products, may be the key to making solar cells that cost less and avoid toxic compounds.

Ethylene glycol functions well in a “continuous flow” reactor — an approach to making thin-film solar cells that is easily scaled up for mass production at industrial levels, they note.

The research, published in Material Letters, a professional journal, also concluded this approach will work with CZTS, or copper zinc tin sulfide, a compound of significant interest for solar cells due to its excellent optical properties and the fact these materials are cheap and environmentally benign.

“The global use of solar energy may be held back if the materials we use to produce solar cells are too expensive or require the use of toxic chemicals in production,” said Greg Herman, an associate professor in the OSU School of Chemical, Biological and Environmental Engineering. “We need technologies that use abundant, inexpensive materials, preferably ones that can be mined in the U.S. This process offers that.”

By contrast, many solar cells today are made with CIGS, or copper indium gallium diselenide. Indium is comparatively rare and costly, and mostly produced in China. Last year, the prices of indium and gallium used in CIGS solar cells were about 275 times higher than the zinc used in CZTS cells.

The technology being developed at OSU uses ethylene glycol in meso-fluidic reactors that can offer precise control of temperature, reaction time, and mass transport to yield better crystalline quality and high uniformity of the nanoparticles that comprise the solar cell — all factors which improve quality control and performance.

This approach is also faster — many companies still use “batch mode” synthesis to produce CIGS nanoparticles, a process that can ultimately take up to a full day, compared to about half an hour with a continuous flow reactor. The additional speed of such reactors will further reduce final costs.