Bioentrepreneur: From slime to tissue culture

May 20, 2011 | Source: New Scientist

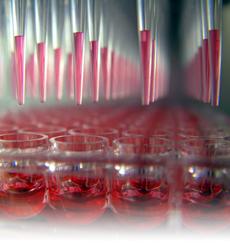

The microbioreactor is supplied sterile and with tubing attached. The user only has to pipette the desired cells and scaffold mix into each well and connect up the tubing to the syringe pump reservoirs (credit: Zyoxel).

TissueFlex, a disposable micro-bioreactor that allows cells to be grown in three dimensions rather than two, is being developed by a start-up firm called Zyoxel.

The micro-bioreactor is made from a biocompatible silicone-based polymer and comprises just two parts: the bottom layer, containing wells, and the top cover, which seals each well. Lengths of needle-like steel tubing, which make the inlet and outlet ports for each well, run along both sides of the micro-bioreactor. Culture medium then flows through the tubing and each well to create a perfused environment.

The technology is based on cell-culture methods developed by researchers at the University of Oxford. The 3-D cell configurations behave much more like tissues than if they were cultured conventionally in a single layer, which means that they can be used to more accurately predict the toxicity and efficacy of new drugs, says Zyoxel founder and CEO Tim Hart.

Zyoxel is currently developing human liver and brain-tissue models. Future plans include looking at incorporating stem-cell technologies into their models and supporting the development of regenerative medicines and for use in in-vitro fertilization (IVF).

.