Building 3D heart tissue with a programmable chip-making device

July 15, 2013

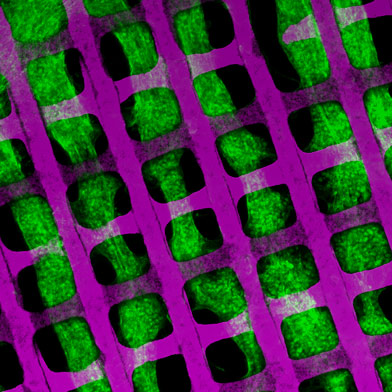

This image of shows multiple thin layers of an elastic “biorubber” polymer (purple) and interwoven muscle tissue (green) formed from neonatal rat heart cells (credit: MIT photo)

By adapting a programmable device used to manufacture integrated circuits, Draper Laboratory researchers have devised a semi-automated process to build three-dimensional heart tissue, MIT Technology Review reports.

Tissue is grown in the lab by “seeding” scaffolds — usually composed of a porous elastic or gelatinous material — with cells meant to develop into specific tissues.

But highly ordered cellular architectures, which are essential for complicated organs like the heart, are much harder to replicate as 3D tissue.

So the researchers made thin sheets of a polymer known as biorubber, patterned with microscale rectangular holes of uniform dimensions. Then they adapted a programmable machine — used by the electronics industry to automatically stack thin material layers and build circuit boards and integrated circuit packages — to precisely stack the porous biorubber sheets.

This work may represent an important step toward implantable heart tissue for humans, but several daunting engineering challenges remain. […]

UPDATE July 16, 2013: “MIT” removed from “Draper Laboratories, which is now an independent research lab.