Carbon nanotubes to replace silicon: IBM

October 29, 2012

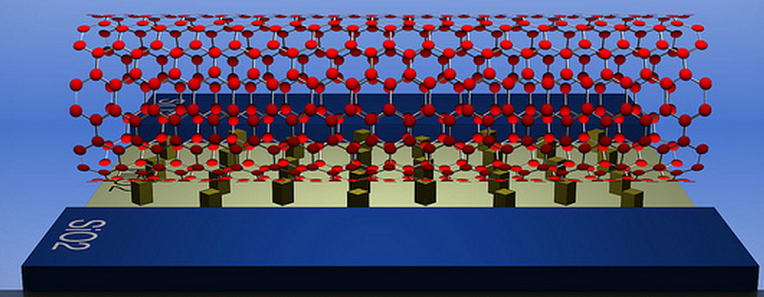

IBM carbon nanotube: The substrate gets dipped in the carbon nanotube solution and the nanotubes attach via a chemical bond to the coating in the HfO2 trenches (credit: IBM)

IBM scientists have precisely placed and tested more than 10,000 carbon nanotube devices in a single chip, using standard semiconductor manufacturing processes — paving the way for carbon technology to replace silicon in future computing and allowing further miniaturization of computing components. The development promises to lead the way for future microelectronics, with controlled placement of individual nanotubes at a density of about a billion per square centimeter.

Silicon transistors are approaching a point of physical limitation. Their increasingly small dimensions, now reaching the nanoscale, will prohibit any gains in performance due to the nature of silicon and the laws of physics. Within a few more generations, classical scaling and shrinkage will no longer yield the sizable benefits of lower power, lower cost and higher speed processors that the industry has become accustomed to.

Carbon nanotubes represent a new class of semiconductor materials whose electrical properties are more attractive than silicon, particularly for building nanoscale transistor devices that are a few tens of atoms across. Electrons in carbon transistors can move easier than in silicon-based devices allowing for quicker transport of data. The nanotubes are also ideally shaped for transistors at the atomic scale, an advantage over silicon. These qualities are among the reasons to replace the traditional silicon transistor with carbon — and coupled with new chip design architectures — will allow computing innovation on a miniature scale for the future.

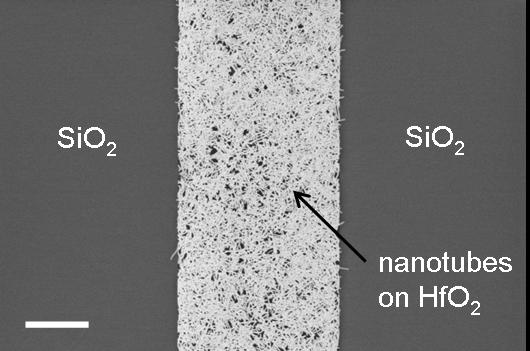

IBM SEM image of carbon nanotubes deposited on a trench coated in hafnium oxide (HfO2) showing extremely high density and excellent selectivity (scale bar: 2 μm). (credit: IBM)

The Road to Carbon

Carbon nanotubes are single atomic sheets of carbon rolled up into a tube. The carbon nanotube forms the core of a transistor device that will work in a fashion similar to the current silicon transistor, but will be better performing. They could be used to replace the transistors in chips that power our data-crunching servers, high performing computers and ultra fast smart phones.

Earlier this year, IBM researchers demonstrated carbon nanotube transistors can operate as excellent switches at molecular dimensions of less than ten nanometers — less than half the size of the leading silicon technology. Comprehensive modeling of the electronic circuits suggests that about a five to ten times improvement in performance compared to silicon circuits is possible.

Sorting out the semiconductors

There are practical challenges for carbon nanotubes to become a commercial technology notably, as mentioned earlier, due to the purity and placement of the devices. Carbon nanotubes naturally come as a mix of metallic and semiconducting species and need to be placed perfectly on the wafer surface to make electronic circuits.

For device operation, only the semiconducting kind of tubes is useful which requires essentially complete removal of the metallic ones to prevent errors in circuits. Also, for large scale integration to happen, it is critical to be able to control the alignment and the location of carbon nanotube devices on a substrate.

To overcome these barriers, IBM researchers developed a novel method based on ion-exchange chemistry that allows precise and controlled placement of aligned carbon nanotubes on a substrate at a high density — two orders of magnitude greater than previous experiments, enabling the controlled placement of individual nanotubes with a density of about a billion per square centimeter.

The process starts with carbon nanotubes mixed with a surfactant, a kind of soap that makes them soluble in water. A substrate is comprised of two oxides with trenches made of chemically-modified hafnium oxide (HfO2) and the rest of silicon oxide (SiO2). The substrate gets immersed in the carbon nanotube solution and the nanotubes attach via a chemical bond to the HfO2 regions while the rest of the surface remains clean.

By combining chemistry, processing and engineering expertise, IBM researchers are able to fabricate more than 10,000 transistors on a single chip.

Furthermore, rapid testing of thousands of devices is possible using high volume characterization tools due to compatibility to standard commercial processes.

As this new placement technique can be readily implemented, involving common chemicals and existing semiconductor fabrication, it will allow the industry to work with carbon nanotubes at a greater scale and deliver further innovation for carbon electronics.