Cooking nanomaterials in a microwave oven to make tomorrow’s solid-state air conditioners and refrigerators

January 11, 2012

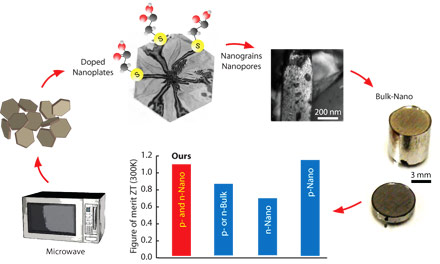

Here’s how to make highly efficient refrigerators and cooling systems requiring no refrigerants and no moving parts: simply cook nanoscale thermoelectric materials with sulfur in a standard microwave oven, according to engineering researchers at Rensselaer Polytechnic Institute (RPI).

Thermoelectric refrigerators using solid-state cooling systems have been available for more than 20 years, but they are still small and highly inefficient because the materials are expensive and difficult to make in large quantities.

So RPI engineers used doping (adding a small amount of a chemical) nanostructured thermoelectric materials with minute amounts of sulfur. The doped materials are obtained by cooking the material and the dopant together for few minutes in a store-bought $40 microwave oven. The resulting powder is formed into pea-sized pellets by applying heat and pressure.

These pellets exhibit properties better than the hard-to-make thermoelectric materials currently available in the marketplace. This new method for creating the doped pellets is much faster, easier, and cheaper than conventional methods of making thermoelectric materials.

The Rensselaer research team can make batches of 10 to 15 grams (enough to make several pea-sized pellets) of the doped nanomaterial in two to three minutes with a microwave oven. Larger quantities can be produced using industrial-sized microwaves ovens.

Beyond refrigerators and air conditioning, the researchers envision this technology could one day be used to cool computer chips.

Rutvik J. Mehta et al., A new class of doped nanobulk high-figure-of-merit thermoelectrics by scalable bottom-up assembly, Nature Materials, 2012 [doi: 10.1038/nmat3213]