Copper film could lower touch-screen, LED, and solar-cell costs

September 26, 2011

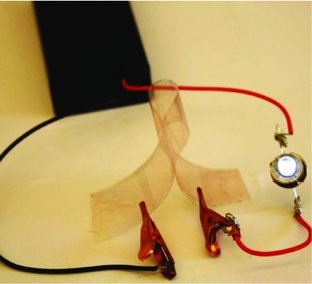

Solution-processable transparent electrodes will facilitate high-throughput production of low-cost photovoltaics. Copper nanowires are coated from solution onto plastic substrates to create high-performance, transparent conducting films that are highly flexible, stable in air, and can carry large currents. (Credit: Ben Wiley, Duke University)

Duke University chemist Ben Wiley and his graduate student have developed a technique to organize copper atoms in water to form long, thin, non-clumped nanowires that are transformed into transparent conductive films and coated onto glass or plastic.

These new nanostructures could drive down the costs of displaying information on cell phones, e-readers and iPads, and also help engineers build foldable electronics and improved solar cells, according to new research.

Why current displays and solar cells are expensive

The film that currently generates pixels in electronic screens are made of indium tin oxide, or ITO. It is highly transparent, which transmits the information well.

But the ITO film must be deposited from a vapor in a process that is a thousand times slower than newspaper printing, and, once the ITO is in the device, it cracks easily. Indium is also an expensive rare earth element, costing as much as $800 per kilogram. Another solution, silver nanowires, will be on the market this year.but silver is even more expensive, at $1400 per kilogram.

These problems have driven worldwide efforts to find less expensive materials that can be coated or printed like ink at much faster speeds to make low-cost, transparent conducting films, Wiley said.

The transparent copper nanowire film solution

Copper, on the other hand, is a thousand times more abundant than indium or silver, and about 100 times less expensive, costing only $9 per kilogram.

In 2010, Wiley and his graduate student Aaron Rathmell showed that it was possible to form a layer of copper nanowires on glass to make a transparent conducting film. But at that time, the performance of the film was not good enough for practical applications because the wires clumped together. The new way of growing the copper nanowires and coating them on glass surfaces eliminates the clumping problem, Wiley said.

He and Rathmell also created the new copper nanowires to maintain their conductivity and form when bent back and forth 1,000 times. In contrast, ITO films’ conduction and structure break after a few bends.

Wiley said the low-cost, high-performance, and flexibility of copper nanowires make them a natural choice for use in the next generation of displays and solar cells. He co-founded a company called NanoForge Corp in 2010 to manufacture copper nanowires for commercial applications.

In early 2011, NanoForge received a $45,000 North Carolina IDEA grant for refinement and scale-up of the manufacturing process of copper nanowires, and it is now filling orders.

With continuing development, copper nanowires could be in screens and solar cells in the next few years, which could lead to lighter and more reliable displays and also to making solar energy more competitive with fossil fuels, Wiley said.

Ref.: Rathmell, A. R. and Wiley, B. J., The Synthesis and Coating of Long, Thin Copper Nanowires to Make Flexible, Transparent Conducting Films on Plastic Substrates, Advanced Materials, 2011; [DOI: 10.1002/adma.201102284]