Engineers create stretchable structures tougher than bulletproof vests

March 27, 2015

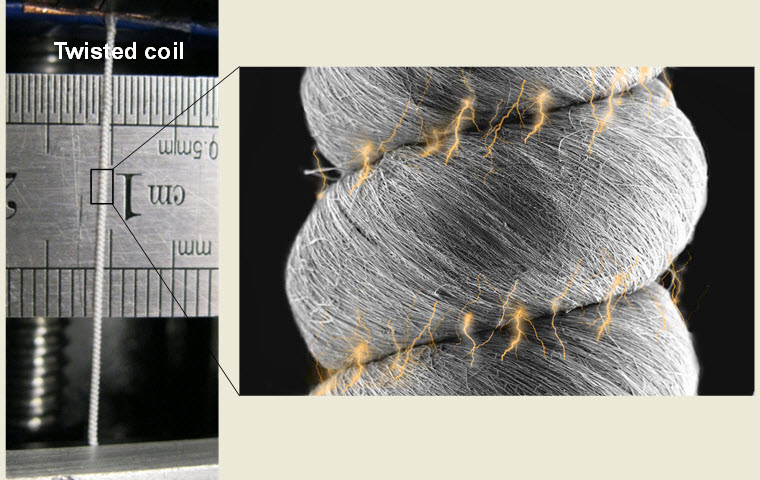

SEM micrographs of a coil fabricated from aligned nanofibers (credit: (credit: Mahmoud Baniasadi et al./ACS Applied Materials and Interfaces)

Researchers at University of Texas at Dallas (UT Dallas) have created a material made from nanofibers that can stretch to up to seven times its length while remaining tougher than Kevlar.

These structures absorb up to 98 joules per gram. Kevlar, often used to make bulletproof vests, can absorb up to 80 joules per gram. The researchers hope the structures will one day form material that can reinforce itself at points of high stress and could potentially be used in military airplanes or other defense applications.

Piezoelectric action

In a study published by ACS Applied Materials and Interfaces, a journal of the American Chemical Society, researchers twisted nanofiber into yarns and coils. The electricity generated by stretching the twisted nanofiber formed an attraction ten times stronger than a hydrogen bond, which is considered one of the strongest forces formed between molecules.

Researchers sought to mimic their earlier work on the piezoelectric action (how pressure forms electric charges) of collagen fibers found inside bone in hopes of creating high-performance materials that can reinforce itself, said Dr. Majid Minary, an assistant professor of mechanical engineering in the University’s Erik Jonsson School of Engineering and Computer Science and senior author of the study.

“We reproduced this process in nanofibers by manipulating the creation of electric charges to result in a lightweight, flexible, yet strong material,” said Minary, who is also a member of the Alan G. MacDiarmid NanoTech Institute. “Our country needs such materials on a large scale for industrial and defense applications.”

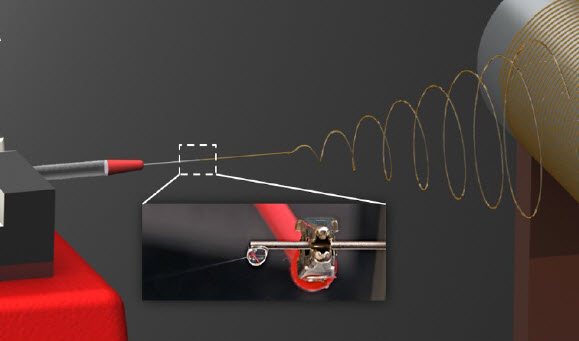

Schematic of the electrospinning process; (inset) jet of PVDF-TrFE solution projected from the tip of the needle toward the collector (credit: Mahmoud Baniasadi et al./ACS Applied Materials and Interfaces)

For their experiment, researchers first spun nanofibers out PVDF and its co-polymer, polyvinvylidene fluoride trifluoroethylene (PVDF-TrFE). Researchers then twisted the fibers into yarns, and then continued to twist the material into coils.

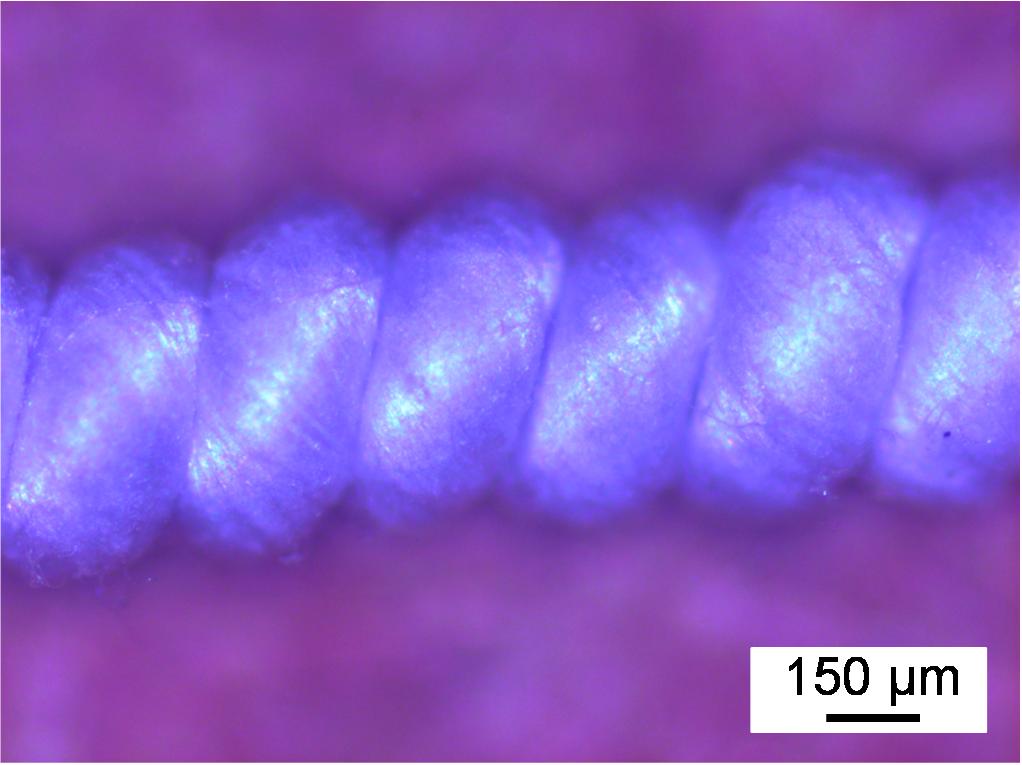

Optical microscope image of a coil (credit: Mahmoud Baniasadi et al./ACS Applied Materials and Interfaces)

Researchers then measured mechanical properties of the yarn and coils, such as how far it can stretch and how much energy it can absorb before failure.

“Our experiment is proof of the concept that our structures can absorb more energy before failure than the materials conventionally used in bulletproof armors,” Minary said. “We believe, modeled after the human bone, that this flexibility and strength comes from the electricity that occurs when these nanofibers are twisted.”

The next step in the research is to make larger structures out of the yarns and coils, Minary said.

A Texas A&M University engineer also participated in the work, which was funded by the Air Force Office of Scientific Research Young Investigator Research Program and the National Science Foundation.

Abstract of High-Performance Coils and Yarns of Polymeric Piezoelectric Nanofibers

We report on highly stretchable piezoelectric structures of electrospun PVDF-TrFE nanofibers. We fabricated nanofibrous PVDF-TrFE yarns via twisting their electrospun ribbons. Our results show that the twisting process not only increases the failure strain but also increases overall strength and toughness. The nanofibrous yarns achieved a remarkable energy to failure of up to 98 J/g. Through overtwisting process, we fabricated polymeric coils out of twisted yarns that stretched up to ∼740% strain. This enhancement in mechanical properties is likely induced by increased interactions between nanofibers, contributed by friction and van der Waals interactions, as well as favorable surface charge (Columbic) interactions as a result of piezoelectric effect, for which we present a theoretical model. The fabricated yarns and coils show great promise for applications in high-performance lightweight structural materials and superstretchable piezoelectric devices and flexible energy harvesting applications.