Engineers give invisibility cloaks a slimmer, stealthier design

July 7, 2015

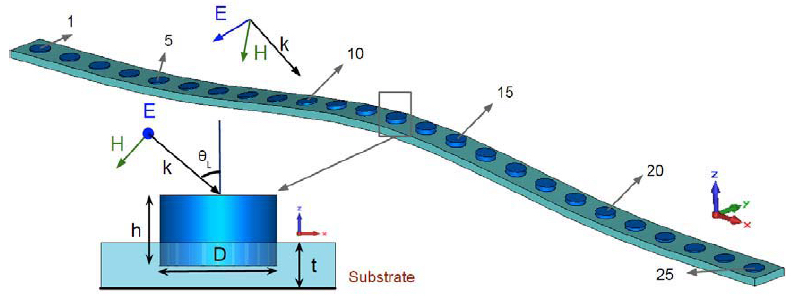

An extremely thin cloaking device is designed using dielectric materials. The cloak is a thin Teflon sheet (light blue) embedded with many small, cylindrical ceramic particles (dark blue). (credit: Li-Yi Hsu/UC San Diego)

Electrical engineers at the University of California, San Diego have developed a new design for a cloaking device that overcomes some of the limitations of existing “invisibility cloaks”: it’s both thin and does not alter the brightness of light around a hidden object.

The technology behind this cloak will have more applications than just invisibility, such as concentrating solar energy and increasing signal speed in optical communications.

“Invisibility may seem like magic at first, but its underlying concepts are familiar to everyone. All it requires is a clever manipulation of our perception,” said Boubacar Kanté, a professor in the Department of Electrical and Computer Engineering at the UC San Diego Jacobs School of Engineering and the senior author of the study. “Full invisibility still seems beyond reach today, but it might become a reality in the near future thanks to recent progress in cloaking devices.”

The idea behind cloaking is to change the scattering of electromagnetic waves — such as light and radar — off an object to make it less detectable to specific frequencies.

One of the drawbacks of cloaking devices is that they are typically bulky.

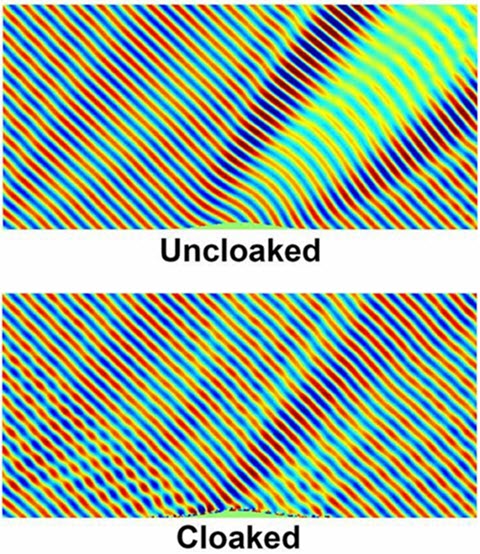

The reflection pattern from an uncloaked object on a flat surface (top) is compared to the reflection pattern of the same object covered with the cloaking device (bottom), which effectively mimics the reflection from a completely flat surface (credit: Li-Yi Hsu/UC San Diego)

“Previous cloaking studies needed many layers of materials to hide an object, [so] the cloak ended up being much thicker than the size of the object being covered,” said Li-Yi Hsu, electrical engineering Ph.D. student at UC San Diego and the first author of the study, which was recently published in an open-access paper in the journal Progress In Electromagnetics Research. “In this study, we show that we can use a thin single-layer sheet for cloaking.”

The researchers say that their cloak also overcomes another fundamental drawback of existing cloaking devices: being “lossy” they loose energy). Cloaks that are lossy reflect light at a lower intensity than what hits their surface.

“Imagine if you saw a sharp drop in brightness around the hidden object, it would be an obvious telltale. This is what happens when you use a lossy cloaking device,” said Kanté. “What we have achieved in this study is a ‘lossless’ cloak. It won’t lose any intensity of the light that it reflects.”

Many cloaks are lossy because they are made with metal particles, which absorb light. The researchers report that one of the keys to their new cloak’s design is the use of non-conductive materials called dielectrics, which, unlike metals, do not absorb light. This cloak includes two dielectrics, a proprietary ceramic and Teflon, which are structurally tailored on a very fine scale to change the way light waves reflect off of the cloak.

Schematic of the cloaking metasurface, discretized with 25 cylinders, and coordinate system. (Inset) unit cell of the metasurface. The bottom black line is the ground plane, the light blue substrate is Teflon, and the dark blue cylinder is ceramic. The incident wave is polarized along the y axis. (credit: Li Yi Hsu et al./Progress In Electromagnetics Research)

A carpet cloak

In their experiments, the researchers specifically designed a “carpet” cloak, which works by cloaking an object sitting on top of a flat surface. The cloak makes the whole system — object and surface — appear flat by mimicking the reflection of light off the flat surface. Any object reflects light differently from a flat surface, but when the object is covered by the cloak, light from different points is reflected out of sync, effectively cancelling the overall revealing distortion of light caused by the object’s shape.

“This cloaking device basically fools the observer into thinking that there’s a flat surface,” said Kanté.

The researchers used Computer-Aided Design software with electromagnetic simulation to design and optimize the cloak. The cloak was modeled as a thin matrix of Teflon in which many small cylindrical ceramic particles were embedded, each with a different height depending on its position on the cloak.

“By changing the height of each dielectric particle, we were able to control the reflection of light at each point on the cloak,” explained Hsu. “Our computer simulations show how our cloaking device would behave in reality. We were able to demonstrate that a thin cloak designed with cylinder-shaped dielectric particles can help us significantly reduce the object’s shadow.”

“Doing whatever we want with light waves is really exciting,” said Kanté. “Using this technology, we can do more than make things invisible. We can change the way light waves are being reflected at will and ultimately focus a large area of sunlight onto a solar power tower, like what a solar concentrator does. We also expect this technology to have applications in optics, interior design and art.”

This particular cloak was designed for a 4.15GHz microwave frequency (close to WiFi), but the approach can be extended to higher frequencies up to the visible, the researchers say in the paper.

This work was supported by a grant from the Calit2 Strategic Research Opportunities (CSRO) program at the Qualcomm Institute at UC San Diego.

Abstract of Extremely thin dielectric metasurface for carpet cloaking

We demonstrate a novel and simple geometrical approach to cloaking a scatterer on a ground plane. We use an extremely thin dielectric metasurface to reshape the wavefronts distorted by a scatterer in order to mimic the reflection pattern of a flat ground plane. To achieve such carpet cloaking, the reflection angle has to be equal to the incident angle everywhere on the scatterer. We use a graded metasurface and calculate the required phase gradient to achieve cloaking. Our metasurface locally provides additional phase to the wavefronts to compensate for the phase difference amongst light paths induced by the geometrical distortion. We design our metasurface in the microwave range using highly sub-wavelength dielectric resonators. We verify our design by full-wave time-domain simulations using micro-structured resonators and show that results match theory very well. This approach can be applied to hide any scatterer under a metasurface of class C1 (first derivative continuous) on a ground plane not only in the microwave regime, but also at higher frequencies up to the visible.