Fully functional loudspeaker is 3D-printed

December 17, 2013

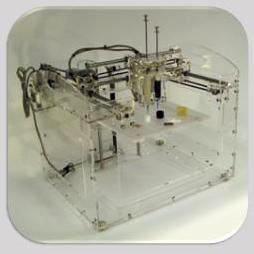

A 3D-printed, fully functional loudspeaker (credit: Jason Koski/Cornell University Photography)

Cornell researchers have 3D-printed a working loudspeaker, seamlessly integrating the plastic, conductive and magnetic parts, and ready for use almost as soon as it came out of the printer.

The loudspeaker is a project led by Apoorva Kiran and Robert MacCurdy, graduate students in mechanical engineering, who work with Hod Lipson, associate professor of mechanical and aerospace engineering and a leading 3-D printing innovator.

The researchers used two Fab@Home printers, which are customizable research printers developed by Lipson that allow for tinkering with different cartridges, control software, and other parameters.

For the conductor, they used a silver ink and for the magnet, they developed a viscous blend of strontium ferrite.

Lipson said he hopes this simple demonstration is just the “tip of the iceberg.” 3-D printing technology could be moving from printing passive parts toward printing active, integrated systems.

But it will be a while before consumers are printing electronics at home, he cautioned. Most printers cannot efficiently handle multiple materials.

It’s also difficult to find mutually compatible materials — for example, conductive copper and plastic coming out of the same printer require different temperatures and curing times. Semiconductors are also a challenge.