How to create a spray-paint battery

June 29, 2012

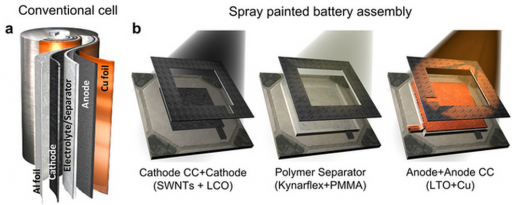

Paintable battery concept. (a) Simplified view of a conventional Li-ion battery, a multilayer device assembled by tightly wound ‘jellyroll’ sandwich of anode-separator-cathode layers. (b) Direct fabrication of Li-ion battery on the surface of interest by sequentially spraying component paints stencil masks tailored to desired geometry and surface. (Credit: N. Singh et al./Scientific Reports)

A lithium-ion battery that can be painted on virtually any surface has been developed by Rice University researchers.

The rechargeable battery, created in the lab of Rice materials scientist Pulickel Ajayan, consists of spray-painted layers, each representing the components in a traditional battery.

“This means traditional packaging for batteries has given way to a much more flexible approach that allows all kinds of new design and integration possibilities for storage devices,” said Ajayan, Rice’s Benjamin M. and Mary Greenwood Anderson Professor in Mechanical Engineering and Materials Science and of chemistry.

Lead author Neelam Singh, a Rice graduate student, and her team spent painstaking hours formulating, mixing and testing paints for each of the five layered components — two current collectors, a cathode, an anode and a polymer separator in the middle.

The materials were airbrushed onto ceramic bathroom tiles, flexible polymers, glass, stainless steel and even a beer stein to see how well they would bond with each substrate.

In the first experiment, nine bathroom tile-based batteries were connected in parallel. One was topped with a solar cell that converted power from a white laboratory light.

When fully charged by both the solar panel and house current, the batteries alone powered a set of light-emitting diodes that spelled out “RICE” for six hours; the batteries provided a steady 2.4 volts.

The researchers reported that the hand-painted batteries were remarkably consistent in their capacities, within plus or minus 10 percent of the target. They were also put through 60 charge-discharge cycles with only a very small drop in capacity, Singh said.

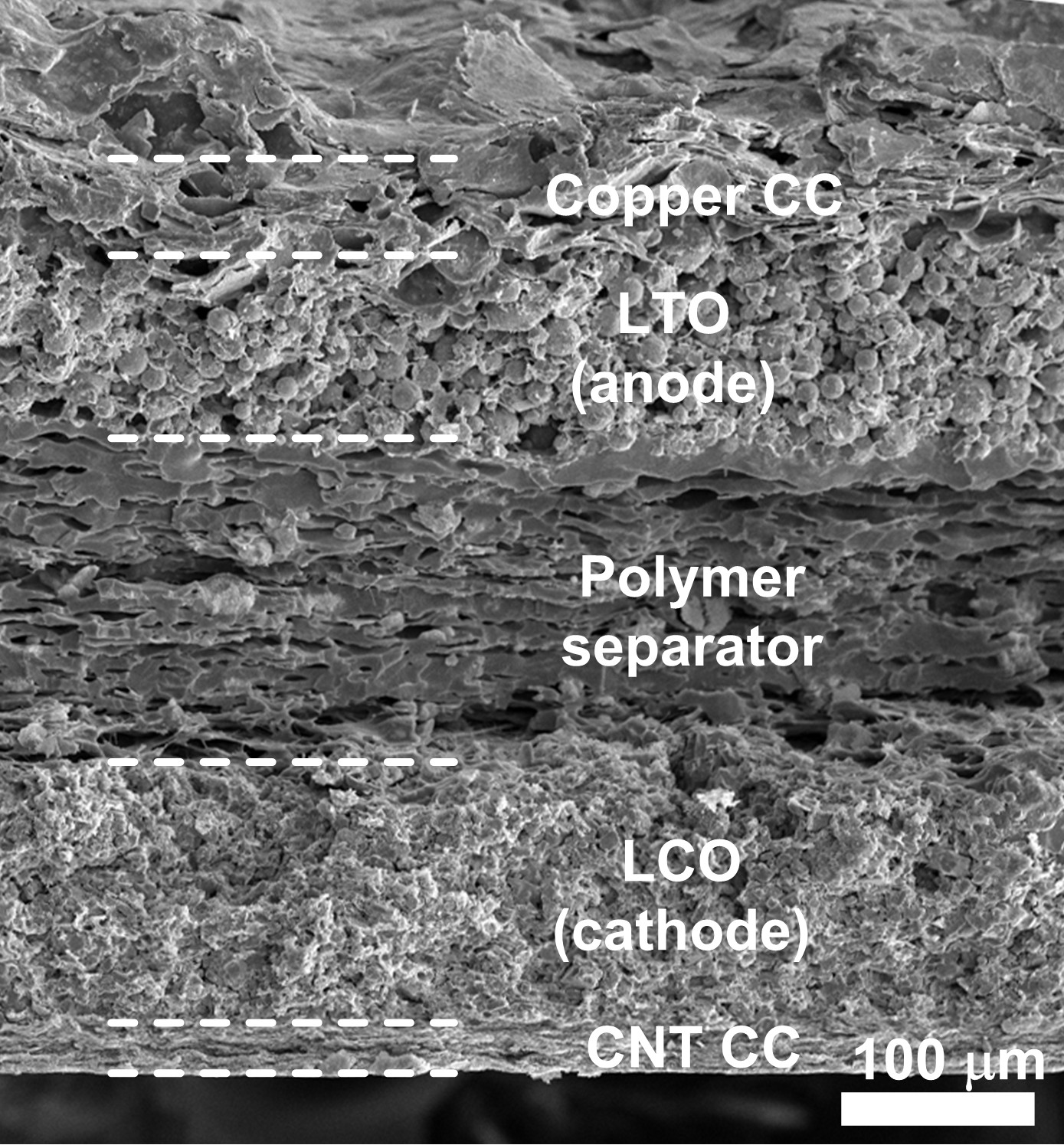

Electron microscope image of spray-painted lithium-ion battery shows its five-layer structure (credit: Ajayan Lab/Rice University)

Each layer is an optimized stew:

- Positive current collector: a mixture of purified single-wall carbon nanotubes with carbon black particles dispersed in N-methylpyrrolidone.

- Cathode: contains lithium cobalt oxide, carbon and ultrafine graphite (UFG) powder in a binder solution.

- Polymer separator paint: uses Kynar Flex resin, PMMA and silicon dioxide dispersed in a solvent mixture.

- Anode: is a mixture of lithium titanium oxide and UFG in a binder

- Negative current collector: commercially available conductive copper paint, diluted with ethanol.

Combining with paintable solar cells

Singh said the batteries were easily charged with a small solar cell. She foresees the possibility of integrating paintable batteries with recently reported paintable solar cells to create an energy-harvesting combination that would be hard to beat. As good as the hand-painted batteries are, she said, scaling up with modern methods will improve them by leaps and bounds. “Spray painting is already an industrial process, so it would be very easy to incorporate this into industry,” Singh said.

The Rice researchers have filed for a patent on the technique, which they will continue to refine. Singh said they are actively looking for electrolytes that would make it easier to create painted batteries in the open air, and they also envision their batteries as snap-together tiles that can be configured in any number of ways.

The Advanced Energy Consortium, the National Science Foundation Partnerships for International Research and Education, Army Research Laboratories and Nanoholdings Inc. supported the research.