How to design a custom robot in minutes without being a roboticist

August 25, 2017

MIT’s new “Interactive Robogami” system will let you design a robot in minutes and then 3D-print and assemble it in about four hours.

“Designing robots usually requires expertise that only mechanical engineers and roboticists have,” says PhD student Adriana Schulz, co-lead author of a paper in The International Journal of Robotics Research and a researcher in MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL). “What’s exciting here is that we’ve created a tool that allows a casual user to design their own robot by giving them this expert knowledge.”

Interactive Robogami uses simulations and interactive feedback with algorithms for design composition, allowing users to focus on high-level conceptual design. Users can choose from a library of more than 50 different bodies, wheels, legs and “peripherals,” as well as a selection of different steps (“gaits”).

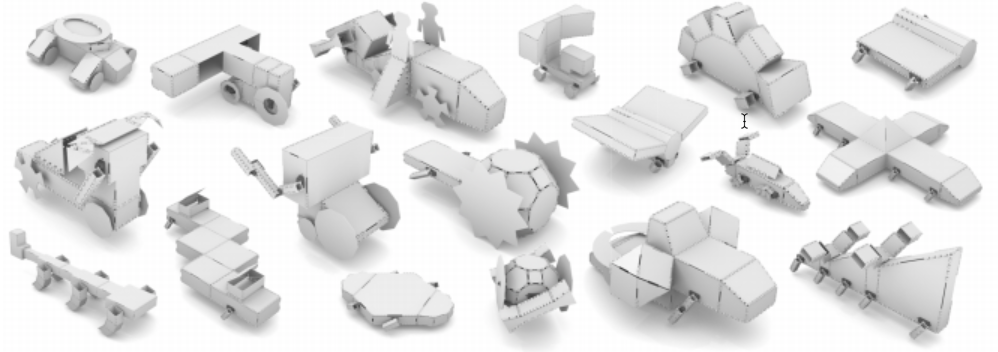

Gallery of designs created by a novice user after a 20-minute training session. Each of the models took between 3 and 25 minutes to design and contains multiple components from the database. (credit: Adriana Schulz et al./The International Journal of Robotics Research)

The system checks to makes sure a design is actually physically possible, analyzing factors such as speed and stability. Once designed, the team’s origami-inspired “3-D print and fold” technique allows for printing the design as flat faces connected at joints, and then folding the design into the final shape, combining the most effective parts of 2D and 3D printing.*

CSAIL director Daniela Rus, a Professor of Electrical Engineering and Computer Science, hopes people will be able to use the system to incorporate robots that can help with everyday tasks, and that similar systems with rapid printing technologies will enable large-scale customization and production of robots.

“These tools enable new approaches to teaching computational thinking and creating,” says Rus. “Students can not only learn by coding and making their own robots, but by bringing to life conceptual ideas about what their robots can actually do.”

This research was supported by the National Science Foundation’s Expeditions in Computing program.

* To test the system, the team used eight subjects who were given 20 minutes of training and asked to perform two tasks: Create a mobile, stable car design in just ten minutes, and create a trajectory to navigate a robot through an obstacle course in the least amount of travel time. The team fabricated a total of six robots, each of which took 10 to 15 minutes to design, 3 to 7 hours to print and 30 to 90 minutes to assemble. The team found that their 3D print-and-fold method reduced printing time by 73 percent and the amount of material used by 70 percent. The robots also demonstrated a wide range of movement, like using single legs to walk, using different step sequences, and using legs and wheels simultaneously.

Abstract of Interactive robogami: An end-to-end system for design of robots with ground locomotion

This paper aims to democratize the design and fabrication of robots, enabling people of all skill levels to make robots without needing expert domain knowledge. Existing work in computational design and rapid fabrication has explored this question of customization for physical objects but so far has not been able to conquer the complexity of robot designs. We have developed Interactive Robogami, a tool for composition-based design of ground robots that can be fabricated as flat sheets and then folded into 3D structures. This rapid prototyping process enables users to create lightweight, affordable, and materially versatile robots with short turnaround time. Using Interactive Robogami, designers can compose new robot designs from a database of print-and-fold parts. The designs are tested for the users’ functional specifications via simulation and fabricated on user satisfaction. We present six robots designed and fabricated using a 3D printing based approach, as well as a larger robot cut from sheet metal. We have also conducted a user study that demonstrates that our tool is intuitive for novice designers and expressive enough to create a wide variety of ground robot designs.