How to form 3-D shapes from flat sheets of graphene

June 30, 2015

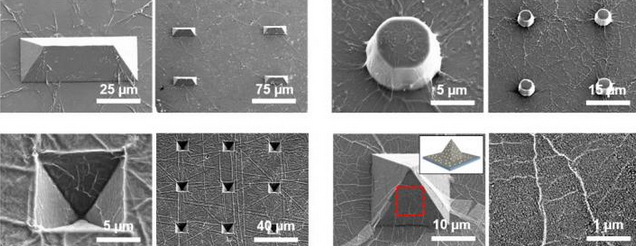

Graphene integration in a variety of different microstructured geometries, including pyramids, pillars, domes, and inverted pyramids (credit: Nam Research Group, University of Illinois)

Researchers from the University of Illinois at Urbana-Champaign have developed a new approach for forming 3D shapes from flat, 2D sheets of graphene, paving the way for future integrated systems of graphene-MEMS hybrid devices and flexible electronics.

Reported methods of using graphene transfer have been mostly limited to planar or curvilinear surfaces due to the challenges associated with fractures from local stress during transfer onto 3D microstructured surfaces, the researchers said.

“To the best of our knowledge, this study is the first to demonstrate graphene integration to a variety of different microstructured geometries, including pyramids, pillars, domes, inverted pyramids, and the 3D integration of gold nanoparticles (AuNPs)/graphene hybrid structures,” explained SungWoo Nam, an assistant professor of mechanical science and engineering at Illinois.

The ability to create 3D structures could allow for highly sensitive 3D sensors, graphene-coated atomic force microscope (AFM) probes, electrode arrays, and biosensing devices that can be conformed to the shape and characteristics of biological systems, and hybrid devices combining “microelectromechanical systems (MEMS) and 2D materials for sensing and actuation, the researchers note in an article in Nano Letters journal.

The process for forming 3D graphene shapes

“Our method utilizes wet-transfer and adaptive substrate-engineering, providing several key advantages over other fabrication/integration methods of 3D graphene,” stated Jonghyun Choi, a graduate student in Nam’s research group and first author of the article.

“Our results demonstrate a simple, versatile, and scalable method to integrate graphene with 3D geometries with various morphologies and dimensions. Not only are these 3D features larger than those reported in previous works, but we also demonstrate the uniformity and damage-free nature of integrated graphene around the 3D features.”

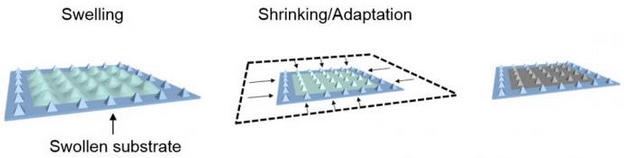

Schematic illustration of the 3D integration of graphene. Left: graphene with supporting layer transferred onto a 3D swollen PDMS substrate. The graphene with supporting layer is suspended (not conformed to the substrate). Center: PDMS substrate shrinking during the evaporation of solvent (e.g., toluene), allowing for three-dimensional adaptation of graphene/supporting layer. Right: Removal of the transfer film with a proper etchant (e.g., acetone for PMMA). (credit: Jonghyun Choi et al./Nano Letters)

The researchers’ robust approach to integrate graphene onto 3D microstructured surfaces, with features that vary from 3.5 to 50 μm, maintains the structural integrity of graphene. The process incorporates three sequential steps: (1.) substrate swelling using a solvent that (2.) shrinks during the evaporation process, allowing graphene to (3.) adapt, or conform to the shape of a prepared substrate, to achieve damage-free, large area integration of graphene on 3D microstructures.

“Our swelling, shrinking, and adaptation steps are optimized to minimize the degree of graphene suspension around the 3D microstructures and facilitate successful 3D integration,” Nam added. “We control the amount of substrate swelling by adjusting the time of immersion in organic solvent and the mixing ratios of monomer and curing agent of the polydimethylsiloxane (PDMS) substrate.”

Detailed scanning electron microscopy, atomic force microscopy, Raman spectroscopy, and electrical resistance measurement studies show that the amount of substrate swelling, as well as the flexural rigidities of the transfer film, affect the integration yield and quality of the integrated graphene.

To demonstrate the versatility of their approach, the researchers applied the process to a variety of 3D microstructured geometries, as well as integrating hybrid structures of graphene decorated with gold nanoparticles onto 3D microstructure substrates, demonstrating the compatibility of the integration method with other hybrid nanomaterials.

This work was supported by the Air Force Office of Scientific Research/Asian Office of Aerospace Research Development Nano Bio Info Technology (NBIT) Phase III Program, the American Chemical Society Petroleum Research Fund, the Korean-American Scientists and Engineers Association, and the National Science Foundation. Experiments were carried out in part in the Frederick Seitz Materials Research Laboratory and the Micro and Nano Technology Laboratory, and the Beckman Institute Imaging Technology Group at Illinois.

Abstract of Three-Dimensional Integration of Graphene via Swelling, Shrinking, and Adaptation

The transfer of graphene from its growth substrate to a target substrate has been widely investigated for its decisive role in subsequent device integration and performance. Thus far, various reported methods of graphene transfer have been mostly limited to planar or curvilinear surfaces due to the challenges associated with fractures from local stress during transfer onto three-dimensional (3D) microstructured surfaces. Here, we report a robust approach to integrate graphene onto 3D microstructured surfaces while maintaining the structural integrity of graphene, where the out-of-plane dimensions of the 3D features vary from 3.5 to 50 μm. We utilized three sequential steps: (1) substrate swelling, (2) shrinking, and (3) adaptation, in order to achieve damage-free, large area integration of graphene on 3D microstructures. Detailed scanning electron microscopy, atomic force microscopy, Raman spectroscopy, and electrical resistance measurement studies show that the amount of substrate swelling as well as the flexural rigidities of the transfer film affect the integration yield and quality of the integrated graphene. We also demonstrate the versatility of our approach by extension to a variety of 3D microstructured geometries. Lastly, we show the integration of hybrid structures of graphene decorated with gold nanoparticles onto 3D microstructure substrates, demonstrating the compatibility of our integration method with other hybrid nanomaterials. We believe that the versatile, damage-free integration method based on swelling, shrinking, and adaptation will pave the way for 3D integration of two-dimensional (2D) materials and expand potential applications of graphene and 2D materials in the future.