How to make perfect nanospheres

March 29, 2013

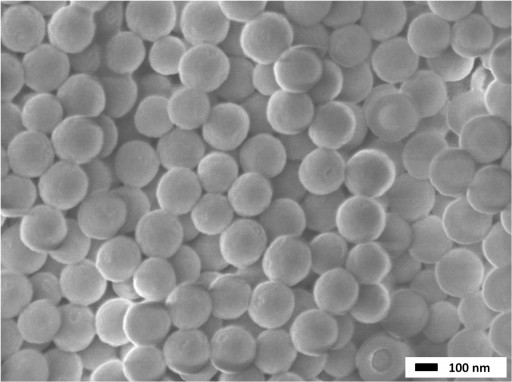

This scanning electron microscopy image depicts the uniform spherical morphology of nanospheres. (Credit: North Dakota State University)

A patent-pending technology to produce nanospheres developed by a research team at North Dakota State University, Fargo, could enable advances across multiple industries, including electronics, manufacturing, and biomedical sectors.

The environmentally-friendly process produces polymer-based nanospheres (tiny microscopic particles) that are uniform in size and shape, while being low-cost and easily reproducible.

The process allows scale-up of operation to high production levels, without requiring specialized manufacturing equipment.

The environmentally friendly process oxidizes ozone in water to produce polymer-based nanospheres, ranging from 70 to 400 nanometers in diameter. They are uniform in size and shape, stay suspended in solution, and are easily removed using a centrifuge.

“The synthesis of the nanospheres is rather simple, with no other chemicals required other than water, ozone, and the small molecules which will become the polymers,” said Dr. Victoria Gelling, associate professor in the Department of Coatings and Polymeric Materials at NDSU. “We also have tight control of the size, as they are beautiful, perfect marbles.”

Given their uniform size and shape, the nanospheres could have uses across multiple industries. According to Gelling, such nanospheres could be used to:

Produce high-performance electronic devices and energy-efficient digital displays

- Create materials with high conductivity and smaller parts for consumer electronics

- Deliver medicine directly to diseased cells in the body

- Provide antibacterial coating on dressing for wounds

- Develop nanosensors to aid in early disease detection

- Create coatings that provide increased protection against corrosion and abrasion

\The patent pending nanospheres technology is available for licensing/partnering through the NDSU Research Foundation.