How to tune graphene properties by introducing defects

July 30, 2015

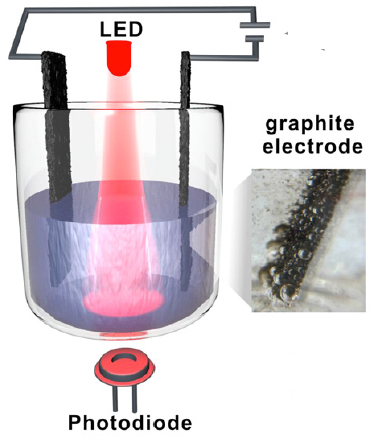

Exfoliation setup. Inset: graphite electrode during exfoliation (credit: Mario Hofmann/Nanotechnology)

Taiwanese researchers reported today (July 30) in the journal Nanotechnology that they have developed a simple electrochemical approach that allows for defects to intentionally be created in graphene, altering its electrical and mechanical properties and making the material more useful for electronic devices and drug delivery, for example.

Current graphene synthesis techniques, such as chemical vapor deposition and reduction of graphene oxide, can only produce graphene with a narrow range of characteristics, limiting the usefulness of produced graphene, the researchers say.

The researchers used a technique called electrochemical synthesis to exfoliate, or peel off graphite flakes into graphene layers. By varying the pulsed voltage, they could change the resulting graphene’s thickness, flake area, and number of defects, altering the properties of graphene.

They also found they need to use a solvent for intercalation (adding a fluid or material between layers) as the necessary first step.

To monitor the evolution of the graphene in the solvent they found that simply tracking the solution’s transparency with an LED and photodiode could give them quantitative information on the efficiency and onset of exfoliation.

They next plan to study the effects of adjusting the pulse durations throughout the exfoliation process to improve the amount of exfoliated graphene and to introduce more complex pulse shapes to selectively produce certain types of graphene defects.

Abstract of Controlling the properties of graphene produced by electrochemical exfoliation

The synthesis of graphene with controllable electronic and mechanical characteristics is of significant importance for its application in various fields ranging from drug delivery to energy storage. Electrochemical exfoliation of graphite has yielded graphene with widely varying behavior and could be a suitable approach. Currently, however the limited understanding of the exfoliation process obstructs targeted modification of graphene properties. We here investigate the process of electrochemical exfoliation and the impact of its parameters on the produced graphene. Using in situ optical and electrical measurements we determine that solvent intercalation is the required first step and the degree of intercalation controls the thickness of the exfoliated graphene. Electrochemical decomposition of water into gas bubbles causes the expansion of graphite and controls the functionalization and lateral size of the exfoliated graphene. Both process steps proceed at different time scales and can be individually addressed through application of pulsed voltages. The potential of the presented approach was demonstrated by improving the performance of graphene-based transparent conductors by 30 times.