Improved thermoelectric materials may give a push to Moore’s law

September 2, 2013

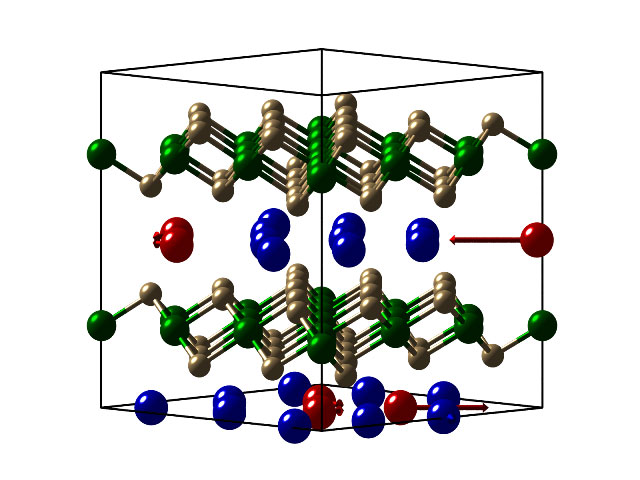

A sodium cobaltate supercell showing a rattling mode comprising mainly displacements of the (red) sodium ions inside tri-vacancy clusters. The introduction of these approximately flat rattling modes at low energies reduces the group velocity along the thermal gradient, suppressing the thermal conductivity by a factor six compared to vacancy-free sodium cobaltate. (Credit: ESRF)

Heat build up in computer chips is a key factor leading to progress in chips hitting the “power wall” — blocking increases in chip speed and slowing down the doubling of chip-transistor density (Moore’s law).

One solution is thermoelectric materials, which convert heat into electricity that can be used for cooling (also used in solid-state refrigerators)*.

But progress in developing these materials has also hit a wall.

That’s because materials exhibiting higher electrical conductivity but lower thermal conductivity (so the heat is not dissipated back into the chip) are not available.

Rattling ions in cages to lower thermal conductivity

Achieving this is theoretically possible by “rattling ions in cages” in crystals with complicated crystal structures, but such crystals have been hard to study.

Now an international team of scientists has discovered a solution. Led by Jon Goff from Royal Holloway, University of London, they conducted a series of experiments on crystals of sodium cobaltate, using X-ray and neutron scattering experiments carried out at the European Synchrotron Radiation Facility (ESRF) and the Institut Laue-Langevin (ILL) in Grenoble.

The experiments were able to identify specific “rattling modes” that suppress thermal conductivity by a factor of six compared to vacancy-free sodium cobaltate.

The scientists believe their approach can also be applied to other substances besides sodium cobaltate, since the approach only requires tiny crystals.

Improved 3D chips, “system on chip” integrated circuits

Oxides are particularly attractive, since they are already extensively employed in integrated circuits and, ultimately, it should be possible to include them in the chip production process, Goff said.

That could be especially important for 3D chips (adding layers adds heat build up) and “system on chip” integrated circuits, which integrate all components of a computer or other device into a single chip.

If we can design better thermoelectric materials, “we will be also able to reduce the energy consumption of cars by converting waste heat in exhausts into electrical power, as well as cooling hot spots on computer chips using solid state refrigerators,” said Goff.

Thermoelectric coolers are also used in air conditioners and in scientific equipment where a rapid response to changes in temperature is required. Power recovery using this method is also useful for off-grid electricity applications, including those in space, he said.

“The development of thermoelectric oxides offers an environmentally clean alternative to current materials that contain elements that are harmful, such as lead, bismuth or antimony, or are in limited supply, such as tellurium,” adds Goff.

* Thermoelectric materials convert waste heat to useful electricity via the “thermoelectric effect“: A thermoelectric device creates voltage when there is a different temperature on each side.