Low-cost thermoelectric device creates electrical power from heat differences

March 2, 2012

Power Felt — a promising new thermoelectric device — converts temperature differences, such as room vs. body — into an electrical current.

Developed by a team of researchers in the Center for Nanotechnology and Molecular Materials at Wake Forest University, it comprises carbon nanotubes locked up in flexible plastic fibers and made to feel like fabric.

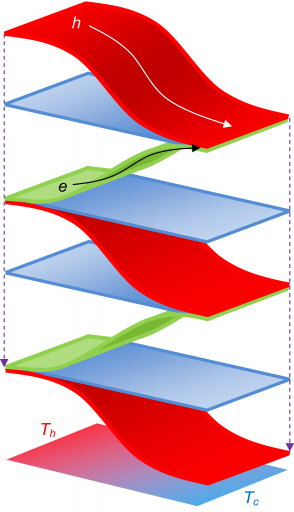

The multilayer film is composed of alternating p-type (red) and n-type (green) nanotube/polymer heterogeneous thin films (~ 20µm thick) with insulating polymer films (blue) between the conduction layers. The layers are pressed together vertically (purple dashed arrows) and heated to ~425K to melt the polymer enough to bond the layers together. When the completed film is subject to a temperature gradient (red-blue gradient), a positive potential difference can be read across the first and last conducting layers governed by the Seebeck Coefficient of the multilayer film. In the p-type layers, the charge carriers are holes (h). The “hot” holes will travel through the p-layer (white arrow) from the hot side (T_h) to the cold side (T_c). In the n-type layers, the charge carriers are electrons (e). The “hot” electrons will travel through the n-layer (black arrow) from the hot side to the cold side. The alternating p/n layers with p/n junctions at opposite ends allows for the direct addition of the absolute value of the Seebeck coefficient for each layer to arrive at the effective overall film Seebeck coefficient (credit: Wake Forest University)

Potential uses for Power Felt include lining automobile seats to boost battery power and service electrical needs, insulating pipes or collecting heat under roof tiles to lower gas or electric bills, lining clothing or sports equipment to monitor performance, an emergency kit powering a weather radio, or wrapping around wound sites to better track patients’ medical needs.

Cost has prevented thermoelectrics from being used more widely in consumer products. Standard thermoelectric devices use a much more efficient compound called bismuth telluride to turn heat into power in products including mobile refrigerators and CPU coolers, but it can cost $1,000 per kilogram.

Like silicon, researchers liken its affordability to demand in volume and think someday Power Felt would cost only $1 to add to a cell phone cover.

Currently, Wake Forest is in talks with investors to produce Power Felt commercially.

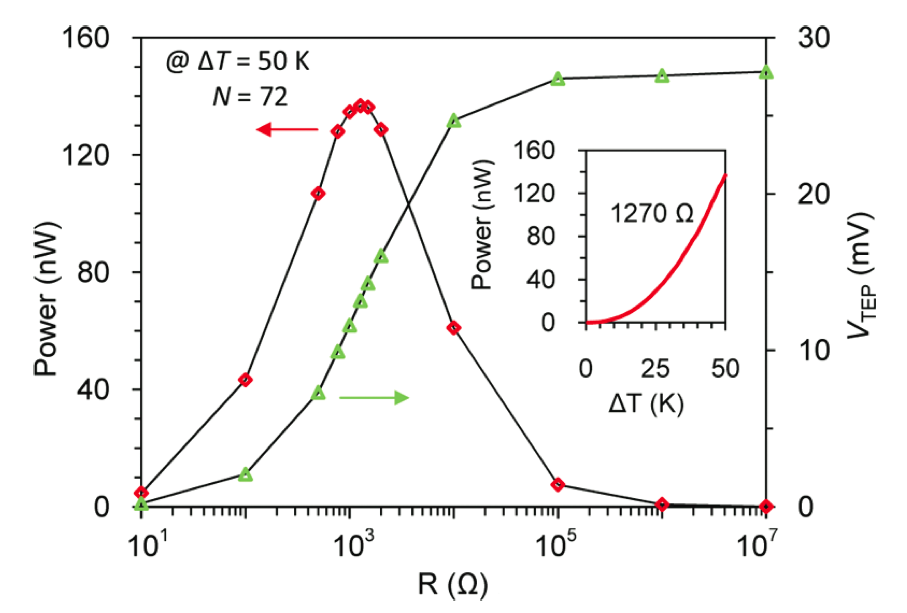

Thermoelectric power and voltage generated by a 72 layer film at delta T = 50 K for varying load resistances. The peak power of 137 nW occurs at a load resistance of 1270. (Credit: Corey A. Hewitt/Nano Letters)

Ref.: Corey A. Hewitt, et al., Multilayered Carbon Nanotube/Polymer Composite Based Thermoelectric Fabrics, Nano Letters, 2012; 120216155234001 [DOI:10.1021/nl203806q]