Model analyzes shape-memory alloys for use in earthquake-resistant structures

February 10, 2012

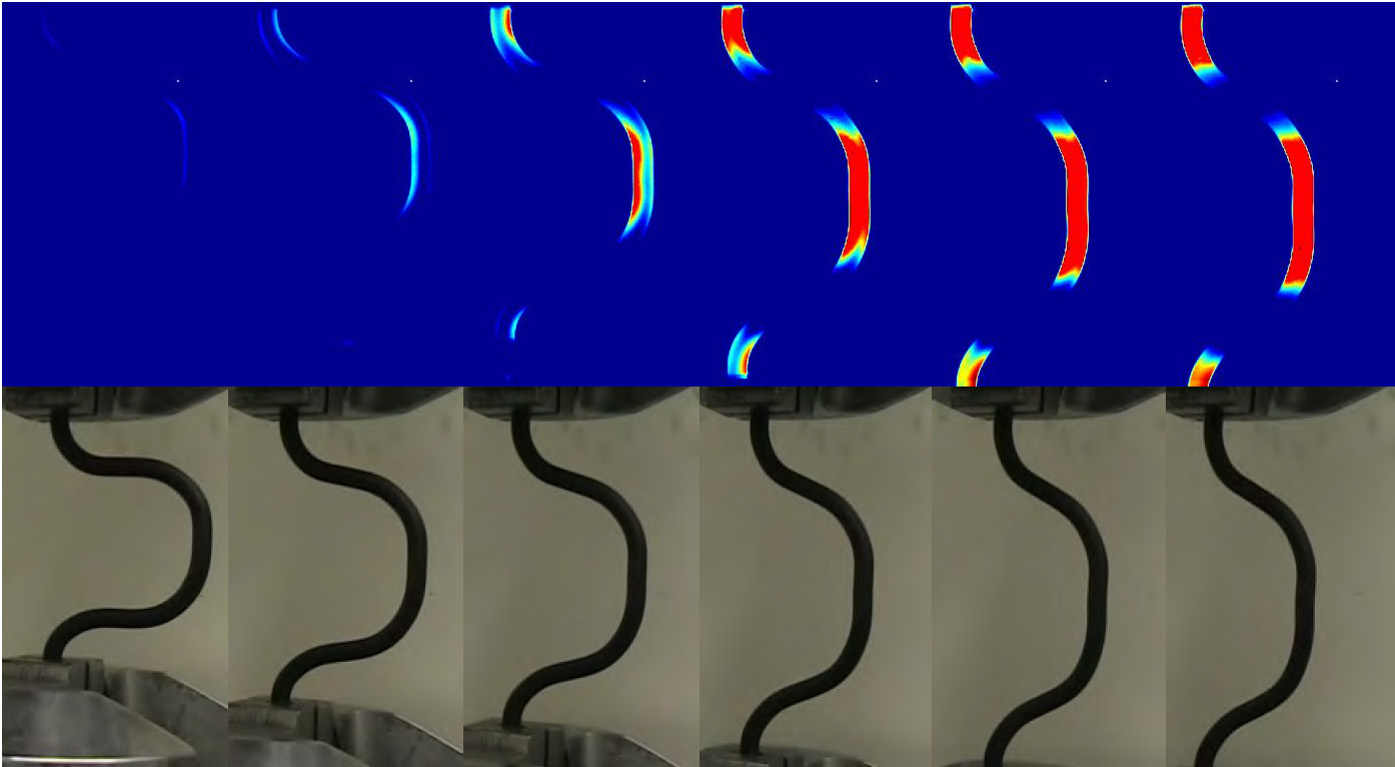

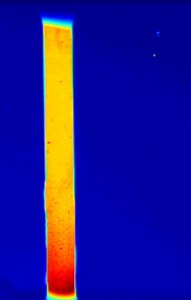

Georgia Tech researchers used a thermal camera to record the variation in surface temperature (top) of a shape-memory alloy experiencing loading and unloading. By inputting this information into their thermo-mechanical model, the researchers were able to accurately predict internal temperature and stress distributions for the material, which is being investigated for use in constructing seismic-resistant structures. (Credit: Reza Mirzaeifar)

Georgia Institute of Technology researchers are analyzing shape-memory alloys for their potential use in constructing seismic-resistant structures.

Recent earthquake damage has exposed the vulnerability of existing structures to strong ground movement.

Shape-memory alloys have the ability to dissipate significant energy without significant degradation or permanent deformation, said Reginald DesRoches, a professor in the School of Civil and Environmental Engineering at Georgia Tech.

The model combines thermodynamics and mechanical equations to assess what happens when shape-memory alloys are subjected to loading from strong motion for a variety of components — cables, bars, plates and helical springs — and for different loading conditions. From that information, they can determine the optimal characteristics of the material for earthquake applications.

To improve the performance of structures during earthquakes, researchers around the world have been investigating the use of “smart” materials, such as shape-memory alloys, which can bounce back after experiencing large loads. The most common shape-memory alloys are made of metal mixtures containing copper-zinc-aluminum-nickel, copper-aluminum-nickel or nickel-titanium.

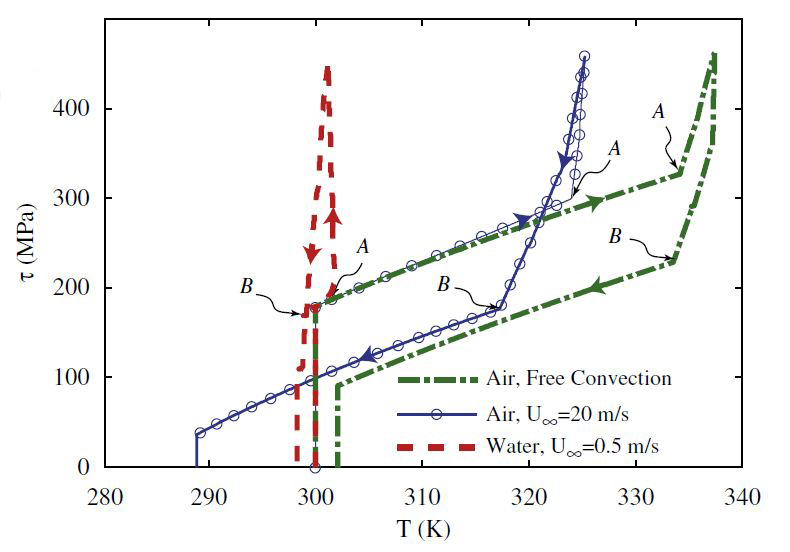

Temperature versus shear stress at the surface of an SMA bar subjected to pure torsion for different ambient conditions (credit: Reza Mirzaeifara et al./International Journal of Non-Linear Mechanics)

Potential applications of shape-memory alloys in bridge and building structures include their use in bearings, columns and beams, or connecting elements between beams and columns.

But before this class of materials can be used, the effect of extreme and repetitive loads on these materials must be thoroughly examined.

The Georgia Tech team found that the generation and absorption of heat during loading and unloading caused a temperature gradient in shape-memory alloys, which caused a non-uniform stress distribution in the material even when the strain was uniform.

Time-lapse video showing the variation in surface temperature of a shape-memory alloy experiencing loading and unloading. By inputting this information into a thermo-mechanical model, Georgia Tech researchers were able to accurately predict internal temperature and stress distributions for the material, which is being investigated for use in constructing seismic-resistant structures. (Click image to watch the video. Credit: Reza Mirzaeifar)

To predict the internal temperature distribution of shape-memory alloys under loading-unloading cycles, which could then be used to determine the stress distribution, the researchers developed a model that used the surface thermal boundary conditions, diameter and loading rate of the alloy as inputs.

The team included ambient conditions in the model because shape-memory alloys for seismic applications could operate in a variety of environments — such as water if used in bridge structures or air if used in building structures — which would produce different rates of heat transfer. The researchers used a thermal camera to record the variation in surface temperature of shape-memory alloys experiencing loading and unloading.

Using their model, the researchers were able to accurately predict internal temperature and stress distributions for shape-memory alloys. The model results were verified with experimental tests.

In one test, they found that a shape-memory alloy loaded at a very slow rate had time to exchange the heat created with the ambient environment and exhibited uniform stress. If it was loaded very rapidly, it did not have enough time to exchange the heat, leading to a non-uniform stress distribution.

In future work, the researchers plan to examine more complicated shapes and the effects of combination loading — tension, bending and torsion — to optimize shape-memory alloys for earthquake applications.

Ref.: Reza Mirzaeifara, Reginald DesRochesb, Arash Yavari, Coupled thermo-mechanical analysis of shape memory alloy circular bars in pure torsion, International Journal of Non-Linear Mechanics, 2012; [DOI:10.1016/j.ijnonlinmec.2012.01.007]