New 3D printing method may allow for fast, low-cost, more-flexible medical implants for millions

May 15, 2017

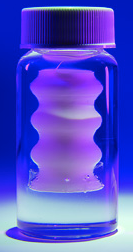

UF Soft Matter | Silicone is 3D-printed into the micro-organogel support material. The printing nozzle follows a predefined trajectory, depositing liquid silicone in its wake. The liquid silicone is supported by the micro-organogel material during this printing process.

University of Florida (UF) researchers have developed a method for 3D printing soft-silicone medical implants that are stronger, quicker, less expensive, more flexible, and more comfortable than the implants currently available. That should be good news for the millions of people every year who need medical devices implanted.

Model 3D-printed silicone trachea implant (credit: University of Florida)

Currently, such devices — such as ports for draining bodily fluids (cerebral spinal fluid in hydrocephalus, for example), implantable bands, balloons, soft catheters, slings and meshes — are mass produced and made through molding processes. To create customized parts for individual patients with molding would be very expensive and could take days or weeks for each job.

The 3D printing method cuts that time to hours, potentially saving lives.

The ability to easily replace silicone implants at low cost is especially important for children, where “implants may need to be replaced frequently as they grow up,” Thomas E. Angelini, an associate professor of mechanical engineering of the UF Department of Mechanical and Aerospace Engineering, explained to KurzweilAI. Angelini is senior author of a paper published May 10, 2017 in the open-access journal Science Advances.

The research could also pave the way for new therapeutic devices that encapsulate and control the release of drugs or small molecules for guiding tissue regeneration or assisting diseased organs, such as the pancreas or prostate, according to lead author Christopher O’Bryan, a UF mechanical and aerospace engineering doctoral student.

UF Soft Matter | Water is pumped from one reservoir to another using a 3D-printed silicone valve. The silicone valve contains two encapsulated ball valves that allow water to be pumped through the valve by squeezing the lower chamber. The silicone valve demonstrates the ability of the UF 3D-printing method to create multiple encapsulated components in a single part — something that cannot be done with a traditional 3D-printing approach.

Abstract of Self-assembled micro-organogels for 3D printing silicone structures

The widespread prevalence of commercial products made from microgels illustrates the immense practical value of harnessing the jamming transition; there are countless ways to use soft, solid materials that fluidize and become solid again with small variations in applied stress. The traditional routes of microgel synthesis produce materials that predominantly swell in aqueous solvents or, less often, in aggressive organic solvents, constraining ways that these exceptionally useful materials can be used. For example, aqueous microgels have been used as the foundation of three-dimensional (3D) bioprinting applications, yet the incompatibility of available microgels with nonpolar liquids, such as oils, limits their use in 3D printing with oil-based materials, such as silicone. We present a method to make micro-organogels swollen in mineral oil, using block copolymer self-assembly. The rheological properties of this micro-organogel material can be tuned, leveraging the jamming transition to facilitate its use in 3D printing of silicone structures. We find that the minimum printed feature size can be controlled by the yield stress of the micro-organogel medium, enabling the fabrication of numerous complex silicone structures, including branched perfusable networks and functional fluid pumps.