New microtweezers may build tiny MEMS structures

January 19, 2012

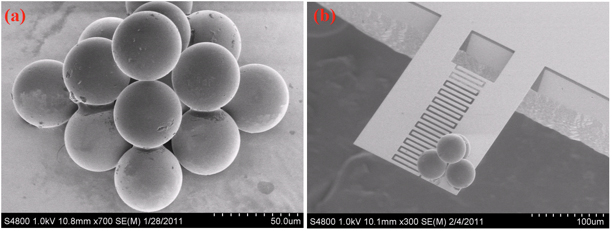

New microtweezers can be used to assemble 40-micron polystyrene spheres (left) into three-dimensional shapes or place microparticles onto the tip of a microcantilever (right) (credit: Birck Nanotechnology Center)

Researchers have created new “microtweezers” capable of manipulating objects to build tiny structures, print coatings to make advanced sensors, and grab and position live stem cell spheres for research.

The microtweezers might be used to assemble structures in microelectromechanical systems (MEMS), which contain tiny moving parts, such as MEMS accelerometers and gyroscopes, currently used in commercial products. A wider variety of MEMS devices, however, could be produced through a manufacturing technology that assembles components like microscopic Lego pieces moved individually into place with microtweezers, said Cagri Savran, an associate professor of mechanical engineering at Purdue University.

“We’ve shown how this might be accomplished easily, using new compact and user-friendly microtweezers to assemble polystyrene spheres into three-dimensional shapes,” he said.

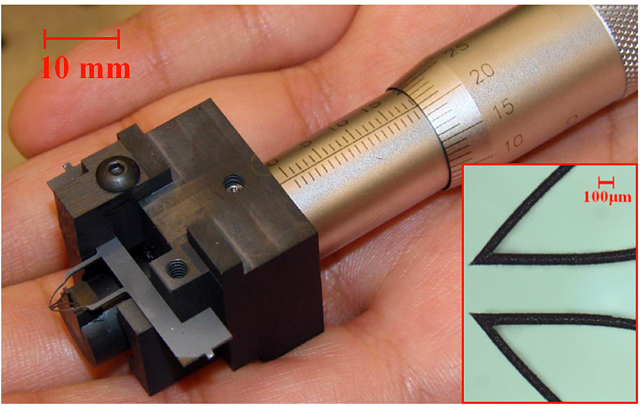

The new microtweezers are capable of manipulating objects to build tiny structures, print coatings to make advanced sensors, and grab and position live stem cell spheres for research (credit: Birck Nanotechnology Center)

How it works

The new tool contains three main parts: a thimble knob from a standard micrometer, a two-pronged tweezer made from silicon, and a “graphite interface” that converts the turning motion of the thimble knob into a pulling-and-pushing action to open and close the tweezer prongs. No electrical power sources are needed, increasing the potential for practical applications. Other types of microtweezers have been developed and are being used in research, but the new design is simpler both to manufacture and operate, Savran said.

The design contains a one-piece “compliant structure” that is springy like a bobby pin or a paperclip. Most other microtweezers require features such as hinges or components that move through heat, magnetism or electricity, complex designs that are expensive to manufacture and relatively difficult to operate in various media, he said.

The tweezers make it feasible to precisely isolate individual stem cell spheres from culture media and to position them elsewhere. Currently, these spheres are analyzed in large groups, but microtweezers could provide an easy way to study them by individually selecting and placing them onto analytical devices and sensors.

“We currently are working to weigh single microparticles, individually selected among many others, which is important because precise measurements of an object’s mass reveal key traits, making it possible to identify composition and other characteristics,” Savran said. “This will now be as easy as selecting and weighing a single melon out of many melons in a supermarket.”

Printing microcantilevers

The microtweezers also could facilitate the precision printing of chemical or protein dots onto “microcantilevers,” strips of silicon that resemble tiny diving boards. The microcantilevers can be “functionalized,” or coated with certain chemicals or proteins that attract specific molecules and materials. Because they vibrate at different frequencies depending on what sticks to the surface, they are used to detect chemicals in the air and water.

Generally, microcantilevers are functionalized to detect one type of substance by exposing them to fluids, Savran said. However, being able to microprint a sequence of precisely placed dots of different chemicals on each cantilever could make it possible to functionalize a device to detect several substances at once. Such a sensing technology also would require a smaller sample size than conventional diagnostic technologies, making it especially practical.

The new microtweezers are designed to be attached easily to “translation stages” currently used in research. These stages are essentially platforms on which to mount specimens for viewing and manipulating. Unlike most other microtweezers, the new device is highly compact and portable and can be easily detached from a platform and brought to another lab while still holding a micro-size object for study, Savran said.

The two-pronged tweezer is micromachined in a “clean room” with the same techniques used to create microcircuits and computer chips.

Ref.: Bin-Da Chan et al, A Compact Manually Actuated Micromanipulator, Journal of Microelectromechanical Systems, 2011 [DOI: 10.1109/JMEMS.2011.2174431]