New paper-like material for lithium-ion batteries could boost electric vehicle range

February 19, 2015

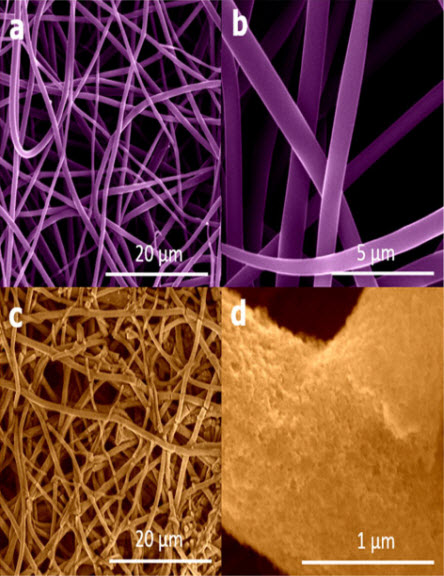

Scanning electron microscope images of (a) SiO2 nanofibers after drying, (b) SiO2 nanofibers under high magnification (c) silicon nanofibers after etching, and (d) silicon nanofibers under high magnification (credit: Zachary Favors et al./Scientific Reports)

Researchers at the University of California, Riverside’s Bourns College of Engineering have developed a novel paper-like material for lithium-ion batteries.

It has the potential to boost by several times the specific energy, or amount of energy that can be delivered per unit weight of the battery.

This paper-like material is composed of sponge-like silicon nanofibers more than 100 times thinner than human hair. It could be used in batteries for electric vehicles and personal electronics.

The research is described in the open-access journal Nature Scientific Reports.

The nanofibers were produced using a technique known as electrospinning: 20,000 to 40,000 volts are applied between a rotating drum and a nozzle, which emits a solution composed mainly of tetraethyl orthosilicate (TEOS), a chemical compound frequently used in the semiconductor industry. The nanofibers are then exposed to magnesium vapor to produce the sponge-like silicon fiber structure.

Conventionally produced lithium-ion battery anodes are made using copper foil coated with a mixture of graphite, a conductive additive, and a polymer binder. But, because the performance of graphite has been nearly tapped out, researchers are experimenting with other materials, such as silicon, which has a specific capacity, or electrical charge per unit weight of the battery, nearly 10 times higher than graphite.

(a) Schematic representation of the electrospinning process and subsequent reduction process. Digital photographs of (b) as-spun SiO2 nanofibers paper, (c) etched silicon nanofiber paper, and (d) carbon-coated silicon nanofiber paper as used in the lithium-ion half-cell configuration. (credit: Zachary Favors et al./Scientific Reports)

Boosting electric-vehicle range

The problem with silicon is that is suffers from significant volume expansion, which can quickly degrade the battery. The silicon nanofiber structure circumvents this issue and allows the battery to be cycled hundreds of times without significant degradation.

This technology will significantly boost the range capabilities of electric vehicles, according to the researchers. It also solves a problem that has plagued free-standing, or binderless, electrodes for years: scalability. Free-standing materials grown using chemical vapor deposition, such as carbon nanotubes or silicon nanowires, can only be produced in very small quantities (micrograms). Favors was able to produce several grams of silicon nanofibers at a time even at the lab scale.

Future work involves implementing the silicon nanofibers into a pouch-cell-format lithium-ion battery, which is a larger scale battery format that can be used in EVs and portable electronics.

The research is supported by Temiz Energy Technologies. The UC Riverside Office of Technology Commercialization has filed patents for inventions reported in the research paper.

Abstract of Towards scalable binderless electrodes: Carbon coated silicon nanofiber paper via Mg reduction of electrospun SiO2 nanofibers

The need for more energy dense and scalable Li-ion battery electrodes has become increasingly pressing with the ushering in of more powerful portable electronics and electric vehicles (EVs) requiring substantially longer range capabilities. Herein, we report on the first synthesis of nano-silicon paper electrodes synthesized via magnesiothermic reduction of electrospun SiO2 nanofiber paper produced by an in situ acid catalyzed polymerization of tetraethyl orthosilicate (TEOS) in-flight. Free-standing carbon-coated Si nanofiber binderless electrodes produce a capacity of 802 mAh g−1 after 659 cycles with a Coulombic efficiency of 99.9%, which outperforms conventionally used slurry-prepared graphite anodes by over two times on an active material basis. Silicon nanofiber paper anodes offer a completely binder-free and Cu current collector-free approach to electrode fabrication with a silicon weight percent in excess of 80%. The absence of conductive powder additives, metallic current collectors, and polymer binders in addition to the high weight percent silicon all contribute to significantly increasing capacity at the cell level.