New printing technology for depositing silver at room temperature may lead to electronics advances

July 2, 2015

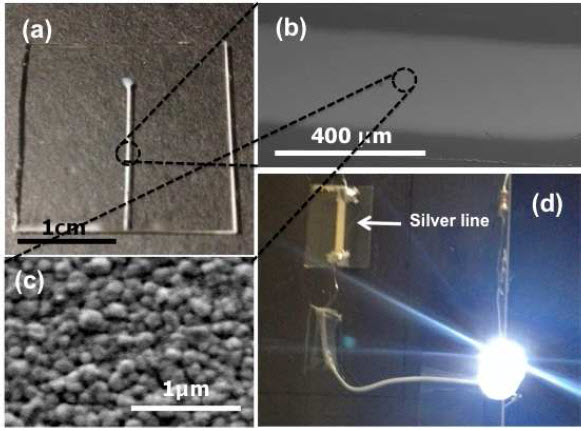

Characterizations of silver line: (a) optical image of the silver line on glass substrate, (b) and (c) low and high-resolution SEM images of silver line, and (d) optical image of LED (credit: Chang-Ho Choi et al./Journal of Materials Chemistry C)

Engineers at Oregon State University (OSU) have invented a way to use silver at room temperature for printed electronics, with broad applications in microelectronics, sensors, energy devices, low emissivity coatings and even transparent displays.

Silver offers advantages in electronic devices because of its conductive and other properties. But the process for using it has required high heat and organic stablizers, followed by post-heating treatments that are required to achieve a highly conductive path. This process has been costly and unsuitable for use on some substrates, such as plastics that might melt or paper that might burn.

“There’s a great deal of interest in printed electronics, because they’re fast, cheap, can be done in small volumes and changed easily,” said Chih-hung Chang, a professor in the OSU College of Engineering. “But the heat needed for most applications of silver nanoparticles has limited their use.”

OSU scientists have solved that problem by using a microreactor to create silver nanoparticles at room temperature without any protective coating, and then immediately printing them onto almost any substrate, with a continuous flow process.

“Because we could now use different substrates such as plastics, glass, or even paper, these electronics could be flexible, very inexpensive and stable,” Chang said. “This could be quite important and allow us to use silver in many more types of electronic applications,” including solar cells, printed circuit boards, low-emissivity coatings, and transparent electronics, he said.

A patent has been applied for on the technology, which is now available for further commercial development. The findings were reported in Journal of Materials Chemistry C.

This research has been supported by the National Science Foundation and Oregon Built Environment and Sustainable Technologies Center (Oregon BEST).

Abstract of Room temperature fabrication and patterning of highly conductive silver features using in situ reactive inks by microreactor-assisted printing

Highly conductive silver was fabricated at room temperature using in situ reactive silver precursor inks by microreactor-assisted printing without any post-processing. Reactive silver nanoinks, synthesized in situ from the microreactor, were directly delivered onto glass and polymeric substrates without any surface treatment to form a highly dense and uniform silver feature. The distribution of the reactive silver nanoinks can be controlled simply by adjusting the flow rate of the continuous flow system. Silver lines were fabricated using the in situ reactive precursors delivered via a micro-channel applicator. The electrical conductivity of the silver film and feature were measured to be around 3.3 × 107 (S m−1), corresponding to about half of the conductivity of bulk silver. The functionality of the silver line was confirmed through the operation of LEDs. This study demonstrates the possibility to fabricate patterned silver features at room temperature from in situ nanoinks without the aid of any post-processing.