New techniques stretch carbon nanotubes, make stronger composites

October 17, 2012

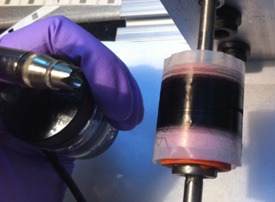

Researchers used a rotating spool to create ribbon-like composite material that have a high percentage of carbon nanotubes, for use in products from airplanes to bicycles (credit: Yuntian Zhu, et al./North Carolina State University)

North Carolina State University researchers have developed new techniques for stretching carbon nanotubes (CNT) and using them to create carbon composites that can be used as stronger, lighter materials in everything from airplanes to bicycles.

By stretching the CNT material before incorporating it into a composite for use in finished products, the researchers straighten the CNTs in the material, which significantly improves its tensile strength — and enhances the stiffness of the composite material and its electrical and thermal conductivity.

State-of-the-art carbon fiber composites are currently used to build airplanes and other products where strong, lightweight materials are desirable. Lighter airplanes, for example, are more fuel efficient. But researchers have long thought that if these composites could be made with CNTs they could be just as strong, but 10 times lighter. Or they could be the same weight, but 10 times stronger.

Creating a strong CNT composite requires four features:

- Long CNTs, which are more effective at carrying loads.

- CNTs aligned in rows.

- A high ratio of CNTs to polymer in the finished composite material (CNTs in the material are held together by a polymer or resin).

- CNTs to be as straight as possible, so that the material bears weight evenly.

For decades, researchers have been unable to achieve these goals. But now a research team, led by Dr. Yuntian Zhu, a professor of materials science and engineering at NC State, has developed a solution.

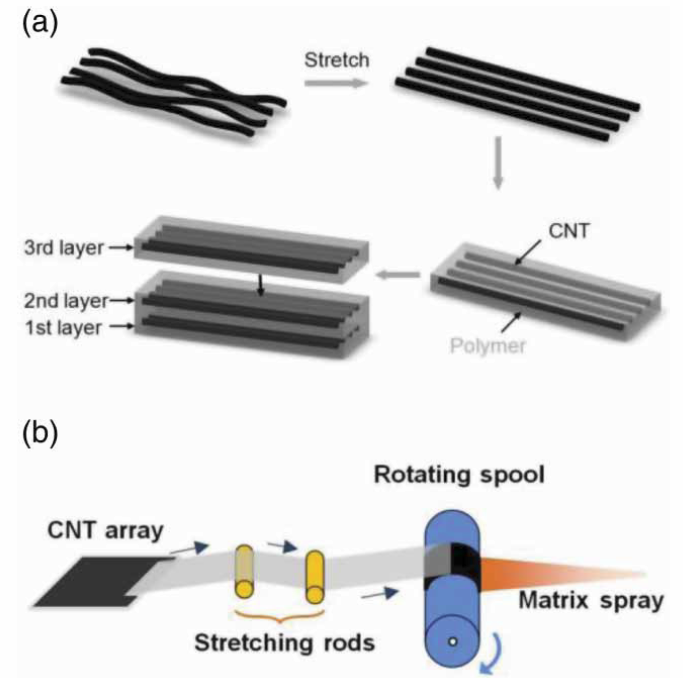

(a) Schematic illustration of the concept of straightening CNTs before embedding them in a polymer matrix in a layer-by-layer fashion. (b) Schematic illustration of the experimental setup for the stretch-winding process. (Credit: Qingwen Li et al./Materials Research Letters)

“The new technique begins with a CNT array,” Zhu says, “which looks like a forest of CNTs growing up out of a flat substrate.” Because the aspect ratio of these CNTs is high, they are long and skinny — not rigid. That means the CNTs are leaning against each other in the array. “By grabbing the CNTs at one end of the array, we are able to pull them over onto their sides — and all of the other CNTs in the array topple in the same direction,” Zhu says. This results in CNTs with good alignment.

These aligned CNTs are then wound onto a rotating spool and sprayed with a polymer solution to bind the CNTs together. This creates a ribbon-like composite material that has a high percentage of CNTs by volume, which can in turn be used to make CNT composite structures for use in finished products like airplanes and bicycles.

But that doesn’t address the need to straighten the CNTs. So Zhu and his team stretched the CNTs as the nanotubes are being pulled onto the rotating spool. This process improves the tensile strength of the CNT composite “ribbon” by approximately 90 percent (to an average of 3.5 gigapascals) and stiffness by more than 100 percent. By straightening the CNTs, the researchers were also able to almost triple the CNT composite’s thermal conductivity, to 40 watts per meter per kelvin. Electrical conductivity was increased by 50 percent to 1,230 siemens per meter.

Researchers involved with the work came from NC State, Suzhou Institute of Nano-Tech and Nano-Bionics, Donghua University, Marshall Space Flight Center, Oak Ridge National Laboratory, and Los Alamos National Laboratory.