New technology senses colors in the infrared spectrum

November 11, 2015

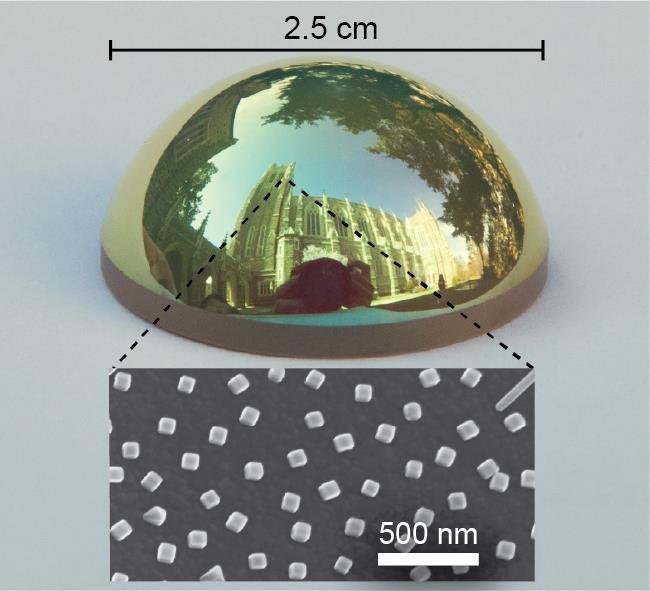

A scanning electron microscope image showing a surface coated with silver nanocubes on a gold surface to image near-infrared light (credit: Maiken Mikkelsen and Gleb Akselrod, Duke University)

Duke University scientists have invented a technology that can identify and image different wavelengths of the infrared spectrum.

The fabrication technique for the system is easily scalable, can be applied to any surface geometry, and costs much less than current light-absorption technologies, according to the researchers. Once adopted, the technique would allow advanced infrared imaging systems to be produced faster and cheaper than today’s counterparts and with higher sensitivity.

The visible-light spectrum, with wavelengths of about 400 to 700 nanometers. The near-infrared region starts just above the red region. (credit: Wikipedia)

Using nanoparticles to absorb specific wavelengths

The technology relies on a physics phenomenon called plasmonics to absorb or reflect specific wavelengths, similar to how stained-glass windows are created (see “Crafting color coatings from nanometer-thick layers of gold and germanium“).

A curved object covered with a coating of 100-nanometer silver cubes that absorbs all red light, leaving the object with a green tint (credit: Maiken Mikkelsen and Gleb Akselrod, Duke University)

The researchers first coat a surface with a thin film of gold through a common process like evaporation. They then put down a few-nanometer-thin layer of polymer, followed by a coating of silver cubes, each one about 100 nanometers (billionths of a meter) in size.

When light strikes the new engineered surface, a specific color gets trapped on the surface of the nanocubes in packets of energy called plasmons, and eventually dissipates into heat. By controlling the thickness of the polymer film and the size and number of silver nanocubes, the coating can be tuned to absorb different wavelengths of light from the visible spectrum (at 650 nm) to the near infrared (up to 1420 nm).

“By borrowing well-known techniques from chemistry and employing them in new ways, we were able to obtain significantly better resolution than with a million-dollar state-of-the-art electron beam lithography system,” said Maiken H. Mikkelsen, the Nortel Networks Assistant Professor of Electrical & Computer Engineering and Physics at Duke University. “This allowed us to create a coating that can fine-tune the absorption spectra with a level of control that hasn’t been possible previously.”

Coating photodetectors to absorb specific wavelengths of near-infrared light would allow novel and cheap cameras to be made that could capture and discriminate different wavelengths.

A better “tricorder” camera

The researchers note in the paper that “plasmonic resonances could be moved deeper into the infrared spectrum by using larger colloidal nanoparticles with larger metallic facets,” including wavelengths in the thermal infrared spectrum.

Colors shown on current thermal infrared-imaging displays are actually based on a simple pseudocolor scheme in which the color displayed is arbitrary — it only represents the amount of thermal radiation (infrared light) that the camera captures, not its wavelength in the electromagnetic spectrum.

That means the technology could be used in a variety of other applications, such as masking the heat signatures of objects such as stealth aircraft (see “Plasmonic cloaking“) or creating a sophisticated “tricorder” camera that shows a person’s temperature at different mid-infrared (thermal) wavelengths (see “Graphene could take night-vision thermal imagers beyond ‘Predator’“).

The study was published online Nov. 9 in the journal Advanced Materials and was supported by the Air Force Office of Scientific Research.

Abstract of Large-Area Metasurface Perfect Absorbers from Visible to Near-Infrared

An absorptive metasurface based on film-coupled colloidal silver nanocubes is demonstrated. The metasurfaces are fabricated using simple dip-coating methods and can be deposited over large areas and on arbitrarily shaped objects. The surfaces show nearly complete absorption, good off-angle performance, and the resonance can be tuned from the visible to the near-infrared.