New transparent metal films may radically reduce costs for smartphone, tablet and TV displays

December 14, 2015

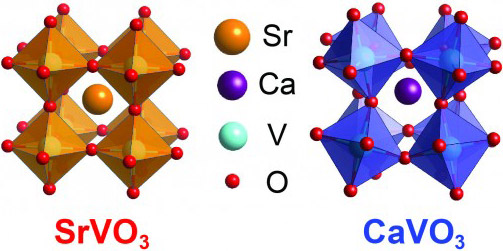

A figure showing the crystal structure of strontium vanadate (orange) and calcium vanadate (blue). The red dots are oxygen atoms arranged in 8 octohedra surrounding a single strontium or calcium atom. Vanadium atoms can be seen inside each octahedron. (credit: Lei Zhang/Penn State)

A new material that is both highly transparent and electrically conductive could make large screen displays, smart windows, touch screens, and solar cells more affordable and efficient, according to materials scientists and engineers at Penn State who have discovered just such a material.

Indium tin oxide (ITO), the transparent conductor that is now used for more than 90 percent of the display market, has been the dominant material for the past 60 years. But in the last decade, the price of indium has increased dramatically. Displays and touchscreen modules have become a main cost driver in mobile devices, such as smartphones and tablets, making up close to 40 percent of the cost.

As as result, while memory chips and processors get cheaper, smartphone and tablet displays get more expensive from generation to generation. Manufacturers have searched for a possible ITO replacement, but until now, nothing has matched ITO’s combination of optical transparency, electrical conductivity, and ease of fabrication.

New display materials

In a paper appearing Tuesday (Dec 15) online in Nature Materials, Roman Engel-Herbert, assistant professor of materials science and engineering, and his team report a new design strategy that approaches the problem from a different angle.

The researchers use thin (10 nanometer) films of an unusual class of materials called correlated metals in which the electrons flow like a liquid. In most conventional metals, such as copper, gold, aluminum or silver, electrons flow like a gas; in correlated metals, such as strontium vanadate and calcium vanadate, they move like a liquid. These correlated metals show a high optical transparency despite their high, metal-like conductivity.

“We are trying to make metals transparent by changing the effective mass of their electrons,” Engel-Herbert says. “We are doing this by choosing materials in which the electrostatic interaction between negatively charged electrons is very large compared to their kinetic energy. As a result of this strong electron correlation effect, electrons ‘feel’ each other and behave like a liquid rather than a gas of non-interacting particles. This electron liquid is still highly conductive, but when you shine light on it, it becomes less reflective, thus much more transparent.”

Less than 5 percent of the cost of current display materials

Currently, indium costs around $750 per kilogram, whereas strontium vanadate and calcium vanadate are made from elements with orders of magnitude higher abundance in the earth’s crust. Vanadium sells for around $25 a kilogram, less than 5 percent of the cost of indium, while strontium is even cheaper than vanadium.

“Our correlated metals work really well compared to ITO. Now, the question is how to implement these new materials in a large scale manufacturing process. From what we understand right now, there is no reason that strontium vanadate could not replace ITO in the same equipment currently used in industry,” says Engel-Herbert.

Along with display technologies, Engel-Herbert and his group plan to combine their new materials with a promising type of solar cell that uses a class of materials called organic perovskites. Developed only within the last half dozen years, these materials outperform commercial silicon solar cells but still require an inexpensive transparent conductor. Strontium vanadate, also a perovskite, has a compatible structure that makes this an interesting possibility for future inexpensive, high-efficiency solar cells.

The Office of Naval Research, the National Science Foundation, and the Department of Energy funded this work.

Abstract of Correlated metals as transparent conductors

The fundamental challenge for designing transparent conductors used in photovoltaics, displays and solid-state lighting is the ideal combination of high optical transparency and high electrical conductivity. Satisfying these competing demands is commonly achieved by increasing carrier concentration in a wide-bandgap semiconductor with low effective carrier mass through heavy doping, as in the case of tin-doped indium oxide (ITO). Here, an alternative design strategy for identifying high-conductivity, high-transparency metals is proposed, which relies on strong electron–electron interactions resulting in an enhancement in the carrier effective mass. This approach is experimentally verified using the correlated metals SrVO3 and CaVO3, which, despite their high carrier concentration (>2.2 × 1022 cm−3), have low screened plasma energies (<1.33 eV), and demonstrate excellent performance when benchmarked against ITO. A method is outlined to rapidly identify other candidates among correlated metals, and strategies are proposed to further enhance their performance, thereby opening up new avenues to develop transparent conductors.