Novel process could let consumers 3D-print metal parts for the first time

November 9, 2014

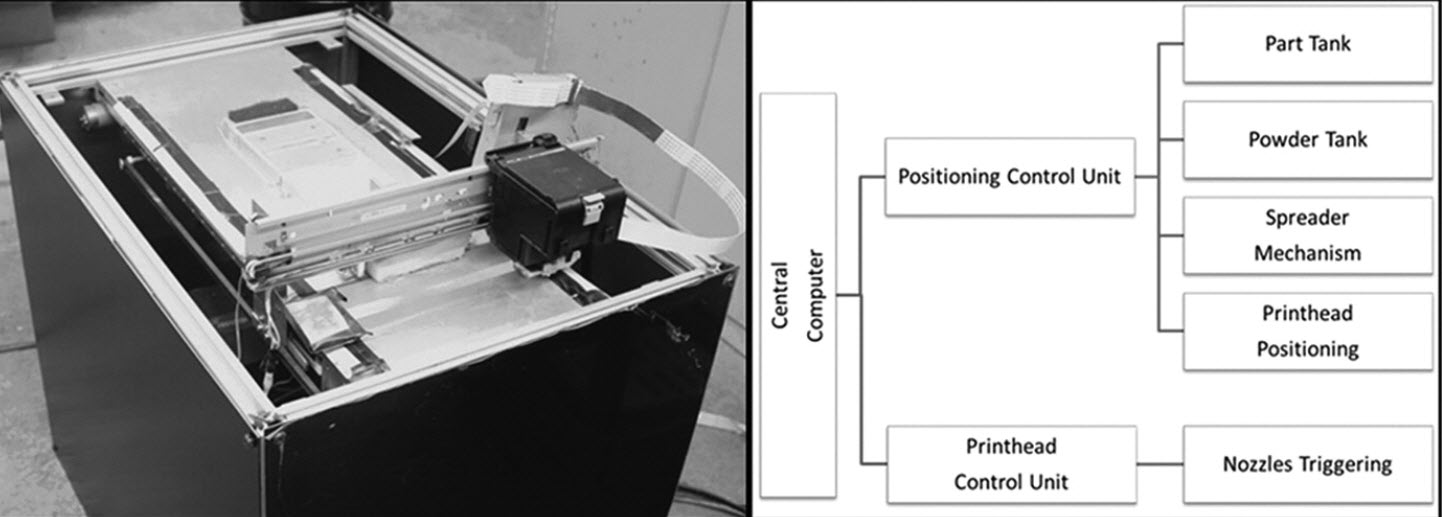

Prototype Selective Inhibition Sintering (SIS) metal machine (left) and block diagram of the machine (right) (credit: Torabi Payman et al./3D Printing and Additive Manufacturing)

A novel 3D printing process called Selective Inhibition Sintering (SIS) promises to allow manufacturing of consumer 3D printers* that can print parts made of high-performance metals, which high-cost industrial 3D printers can already do.

The new process, developed at the Center for Rapid Automated Fabrication Technologies at USC, is based on existing low-cost inkjet printing technology. It differs from traditional research in powder sintering* (a process of fusing materials using heat and pressure), which focuses on enhancing sintering

CAD model of a crescent wrench (left) and the resulting printed part (right) (credit: Torabi Payman et al./3D Printing and Additive Manufacturing)

Instead, SIS prevents sintering in selected regions of each powder layer, using a sintering inhibitor — the inverse of traditional metal additive-manufacturing processes.

The engineers explain this innovative process, show sample parts printed using the technology, and discuss the next steps in research and development in an article in the journal 3D Printing and Additive Manufacturing, available free until December 6, 2014.

* According to the 2014 Wohler’s Report, consumer 3D printers are classified as those that cost less than $5,000.

** The process of forming a solid mass from powdered material by heatand/or pressureto the point of liquefaction, but without actually melting it.

Abstract of 3D Printing and Additive Manufacturing

The current 3D printing market is in need of a solution in which high performance meets low cost. Consumer 3D printers are predominantly based on fused filament fabrication technology, and while they feature a low cost, they only offer a limited selection of plastic materials. On the other hand, industrial additive manufacturing (AM) machines offer a variety of materials, including high-performance metals, with printed parts capable of tackling industrial applications. Unfortunately, these machines come at a high cost. This research aims to explore the application of a novel AM process called selective inhibition sintering (SIS) for use in a consumer-priced metal AM machine. Sample parts are printed and presented, along with a discussion of the results and future work necessary.