Piezotronics produces electrical signals from biomechanical actions

July 28, 2011

Georgia Institute of Technology researchers have demonstrated a new type of piezoelectric resistive switching device in which the write-read access of memory cells is controlled by electromechanical modulation.

Operating on flexible substrates, arrays of these devices could provide a new way to interface the mechanical actions of the biological world to conventional electronic circuitry.

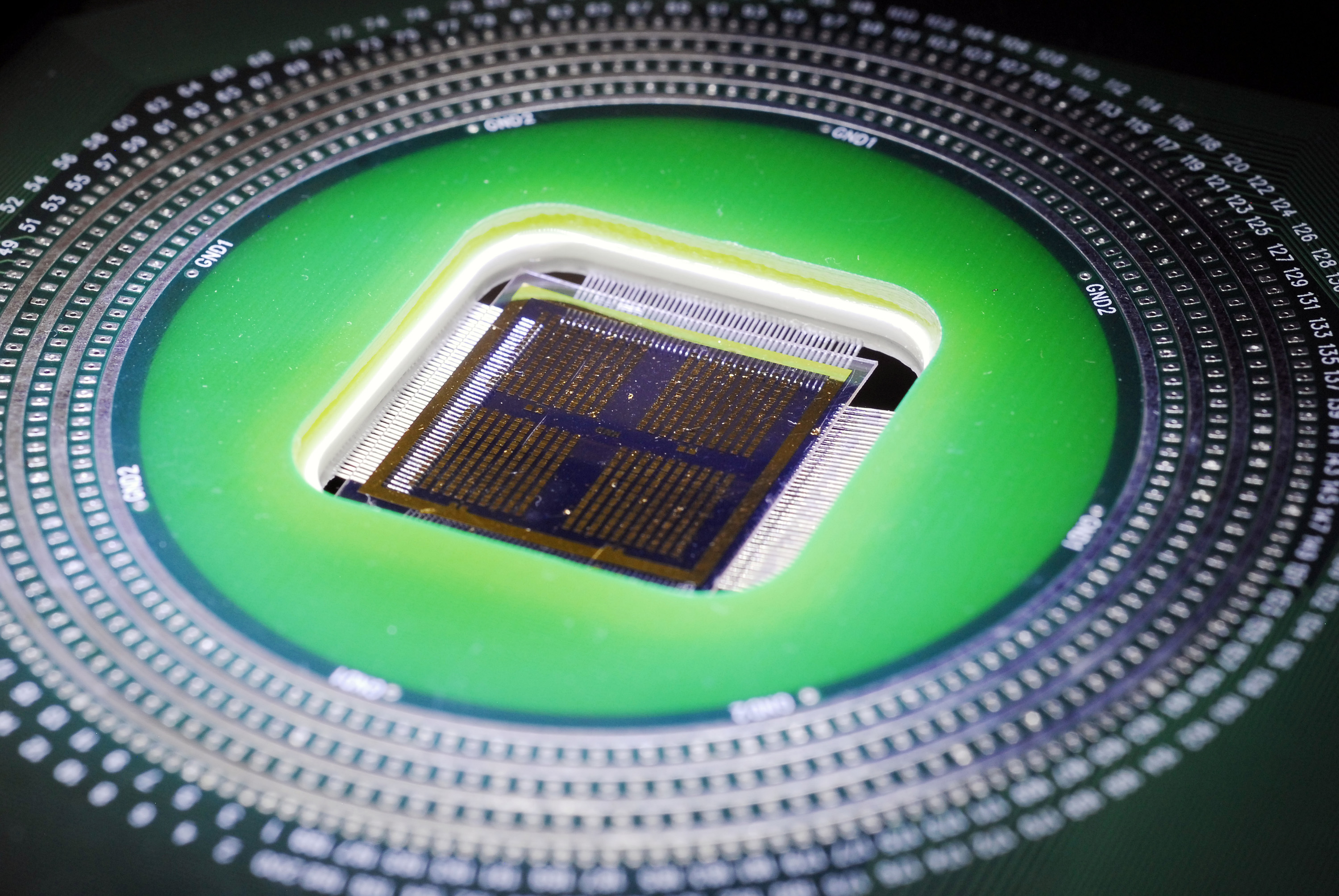

An array of piezoelectrically modulated resistive memory (PRM) cells on which metal electrodes have been patterned using lithography (credit: Gary Meek)

These piezoelectrically modulated resistive memory (PRM) devices use the resistance of piezoelectric semiconducting materials such as zinc oxide to produce a charge potential when they are mechanically deformed or otherwise put under strain (the piezoelectric effect).The charge creates polarity in the nanowires and increases the electrical resistance, much like gate voltage in a conventional transistor.

The piezotronic (piezoelectric-based electronics) switching affects current flowing in just one direction, depending whether the strain is tensile or compressive. That means the memory stored in the piezotronic devices has both a sign and a magnitude. The information in this memory can be read, processed and stored through conventional electronic means.

The mechanical strain could come from mechanical activities as diverse as signing a name with a pen, the motion of an actuator on a nanorobot, or biological activities of the human body such as a heart beating.

Operating on flexible substrates, arrays of these devices could provide a new way to interface the mechanical actions of the biological world to conventional electronic circuitry, the researchers said.

These piezotronic memory elements provide another component needed for fabricating complete self-powered nanoelectromechanical systems (NEMS) on a single chip. The research team has already demonstrated other key elements such as nanogenerators, sensors and wireless transmitters.

The zinc oxide nanowires are about .5 micron in diameter and about 50 microns long. They are produced with a physical vapor deposition process that uses a high-temperature furnace. The resulting structures are then treated with oxygen plasma to reduce the number of crystalline defects and control their conductivity.

Ref.: Wenzhuo Wu, Zhong Lin Wang, Piezotronic Nanowire-Based Resistive Switches As Programmable Electromechanical Memories, Nano Letters,, 2011; 11 (7): 2779 [DOI: 10.1021/nl201074a]