Plugging up leaky graphene

May 8, 2015

(credit: MIT)

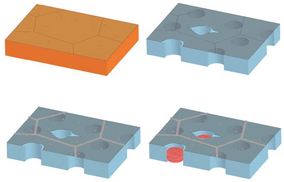

Graphene’s unique properties make it a potentially ideal membrane for water filtration or desalination. but the process of making it into ultrathin membranes creates leaky defects. So MIT engineers and associates have devised a two-step process to repair these leaks.

As shown in the illustration (top left) graphene is fabricated on a copper surface — a process that can create intrinsic defects in graphene. After lifting the graphene and depositing it on a porous surface (top right), the transfer creates further holes and tears.

To fix the defects, the team used atomic layer deposition in a vacuum chamber to deposit hafnium (in gray) to seal intrinsic cracks (bottom left), then plugged the remaining holes with nylon (in red), via interfacial polymerization (bottom right).

The researchers then submerged the membrane at the interface of the two solutions, where nylon plugs formed only in tears and holes, effectively sealing the remaining defects.

The researchers then etched nanoscale pores in the graphene — small enough to let water molecules through, but not larger contaminants. They found that the membrane rejected up to 90 percent of larger molecules.

First success in plugging graphene’s leaks

Combining these techniques, the researchers were able to engineer a relatively large defect-free graphene membrane — about the size of a penny. (To be exploited as a filtration membrane, graphene would have to be manufactured at a scale of centimeters, or larger.)

Rohit Karnik, an associate professor of mechanical engineering at MIT, says the group’s results, published in the journal Nano Letters, represent the first success in plugging graphene’s leaks.

“The current types of membranes that can produce freshwater from saltwater are fairly thick, on the order of 200 nanometers,” says Sean O’Hern, a former graduate research assistant at MIT and the paper’s first author. “The benefit of a graphene membrane is, instead of being hundreds of nanometers thick, we’re on the order of three angstroms — 600 times thinner than existing membranes. This enables you to have a higher flow rate over the same area.”

The preliminary tests suggest that graphene may be a viable alternative to existing filtration membranes, although Karnik says techniques to seal its defects and control its permeability will need further improvements.

“Water desalination and nanofiltration are big applications where, if things work out and this technology withstands the different demands of real-world tests, it would have a large impact,” Karnik says. “But one could also imagine applications for fine chemical- or biological-sample processing, where these membranes could be useful. And this is the first report of a centimeter-scale graphene membrane that does any kind of molecular filtration. That’s exciting.”

Engineers at Oak Ridge National Laboratory and King Fahd University of Petroleum and Minerals (KFUPM) were also involved the research, which was supported in part by the Center for Clean Water and Clean Energy at MIT and KFUPM, the U.S. Department of Energy, and the National Science Foundation.

Abstract of Nanofiltration across Defect-Sealed Nanoporous Monolayer Graphene

Monolayer nanoporous graphene represents an ideal membrane for molecular separations, but its practical realization is impeded by leakage through defects in the ultrathin graphene. Here, we report a multiscale leakage–sealing process that exploits the nonpolar nature and impermeability of pristine graphene to selectively block defects, resulting in a centimeter-scale membrane that can separate two fluid reservoirs by an atomically thin layer of graphene. After introducing subnanometer pores in graphene, the membrane exhibited rejection of multivalent ions and small molecules and water flux consistent with prior molecular dynamics simulations. The results indicate the feasibility of constructing defect-tolerant monolayer graphene membranes for nanofiltration, desalination, and other separation processes.