‘Porous liquid’ invention could lead to improved carbon capture

November 13, 2015

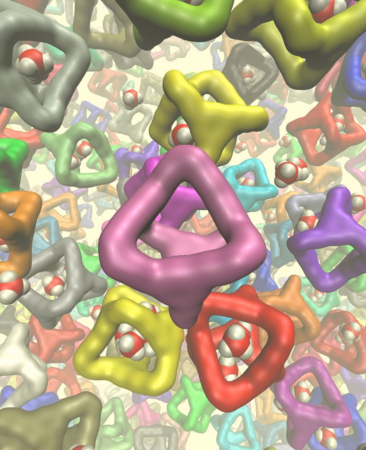

World’s first “porous liquid” (credit: Queen’s University Belfast)

Scientists at Queen’s University Belfast, Northern Ireland, and partners have invented a “porous liquid” that can dissolve unusually large amounts of gas, with the potential for a wide range of new uses, including carbon capture.

They designed the new liquid from the bottom up, designing the shapes of the “cage molecules” to form empty holes. The researchers say the concentration of unoccupied cages can be around 500 times greater than in other molecular solutions that contain cavities, enabling an eightfold increase in the solubility of methane gas, for example.

The results of their research were published Nov. 12 in the journal Nature.

Abstract of Liquids with permanent porosity

Porous solids such as zeolites and metal–organic frameworks are useful in molecular separation and in catalysis, but their solid nature can impose limitations. For example, liquid solvents, rather than porous solids, are the most mature technology for post-combustion capture of carbon dioxide because liquid circulation systems are more easily retrofitted to existing plants. Solid porous adsorbents offer major benefits, such as lower energy penalties in adsorption–desorption cycles, but they are difficult to implement in conventional flow processes. Materials that combine the properties of fluidity and permanent porosity could therefore offer technological advantages, but permanent porosity is not associated with conventional liquids5. Here we report free-flowing liquids whose bulk properties are determined by their permanent porosity. To achieve this, we designed cage molecules that provide a well-defined pore space and that are highly soluble in solvents whose molecules are too large to enter the pores. The concentration of unoccupied cages can thus be around 500 times greater than in other molecular solutions that contain cavities, resulting in a marked change in bulk properties, such as an eightfold increase in the solubility of methane gas. Our results provide the basis for development of a new class of functional porous materials for chemical processes, and we present a one-step, multigram scale-up route for highly soluble ‘scrambled’ porous cages prepared from a mixture of commercially available reagents. The unifying design principle for these materials is the avoidance of functional groups that can penetrate into the molecular cage cavities.