Print me a phone

July 30, 2012

New ways of printing electronics in three dimensions make it possible to incorporate circuitry and components into the material a product is made from (like a case) and could revolutionize the way electronic goods are made, The Economist reports.

By making silver into particles just five nanometers in size, Xerox has produced a silver ink that melts at less than 140°C. That allows it to be printed using inkjet and other processes relatively cheaply.

Xerox’s PARC research center is developing ways to print circuits for various components, including flexible display screens, sensors and antennas for radio-frequency security tags.

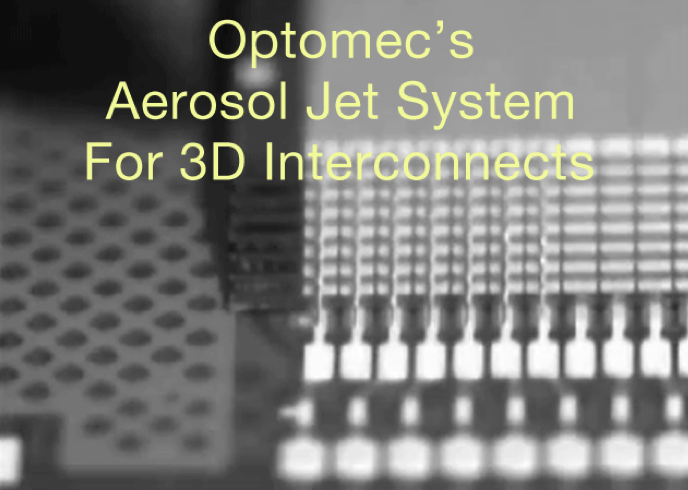

With the emergence of additive-manufacturing techniques, it starts to become possible to print such things directly onto the product itself. Optomec has developed additive-manufacturing systems for a variety of industries. It can print electronics directly onto a pair of glasses, for augmented reality, or a “smart wing” for a small drone.

Its Aerosol Jet process atomizes nanoparticle-based print materials into microscopic droplets, which are then focused, using a sheath of gas, into a precise jet stream directed by a nozzle and can print electronic features smaller than a hundredth of a millimeter wide from a variety of materials.

Optomec says it is developing applications that could provide some of the necessary steps to print a complete phone (except chips).