Robots to reduce cost of building aircraft

September 20, 2011

Fraunhofer researchers have come up with a concept for a flexible assembly-line concept using robots to build future aircraft more flexibly and economically.

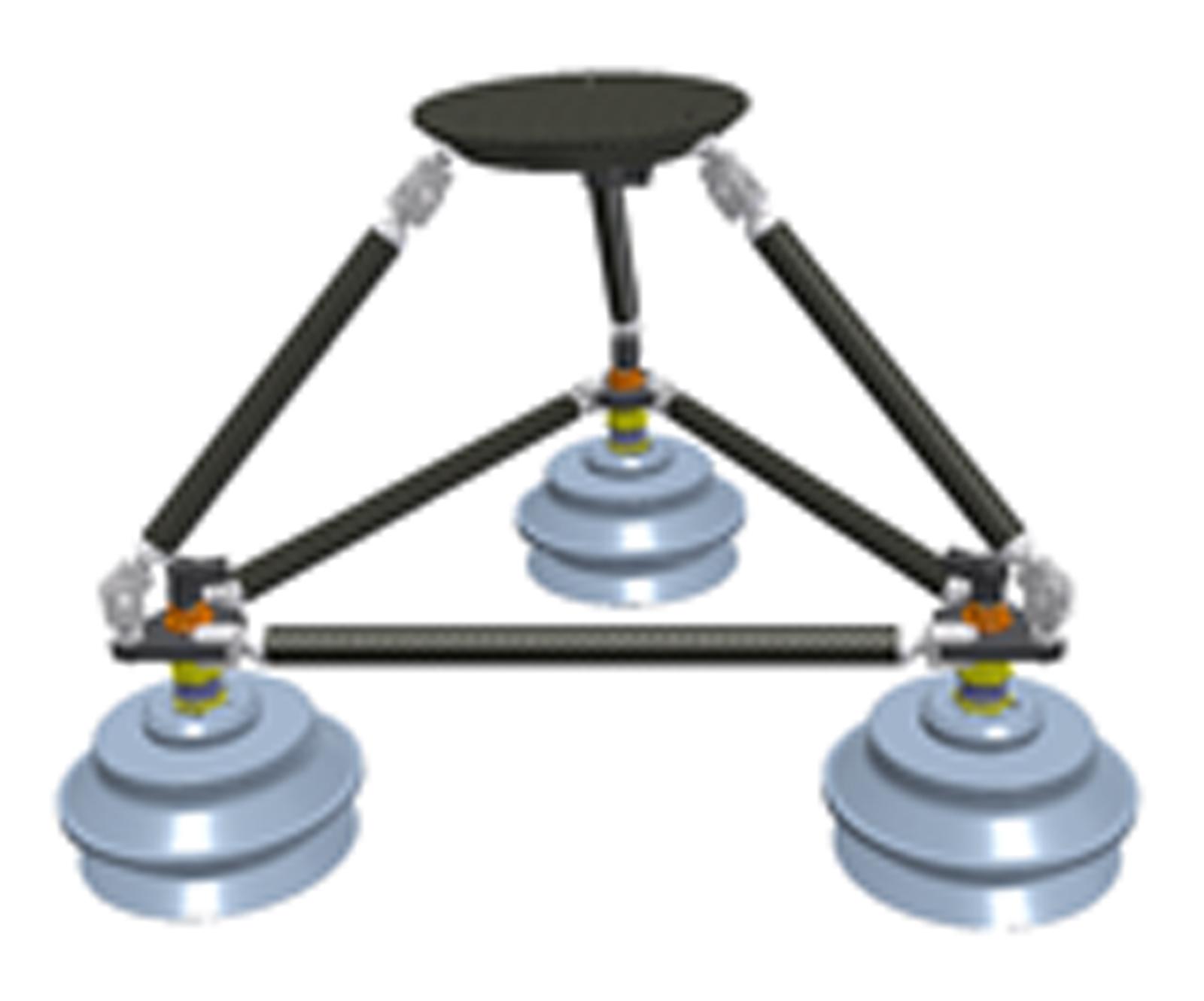

The aircraft will be machined and assembled by small industrial robots, as in the automotive sector. The key element of the assembly line is a versatile component gripper made of lightweight CFRP (carbon fiber reinforced plastic) that can deal flexibly with various geometries of aircraft components.

A high-precision image-recognition system will measure the components exactly during assembly. Software will calculate the precise position in which the robot has to hold the workpiece to make everything fits together perfectly at a demanding 0.2 millimeter tolerance.