Self-healing polymers fix scratches using light rather than heat

April 21, 2011

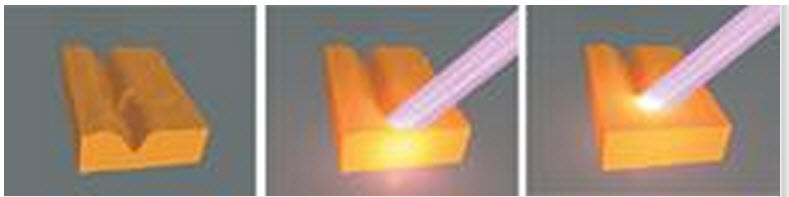

Where irradiated with ultraviolet light, the originally solid polymer material is liquefied and can quickly fill up cracks. After the light is switched off, the material solidifies and the original properties are restored (credit: Marc Pauchard for Adolphe Merkle Institute, Case Western Reserve University, US Army Research Laboratory)

Self-healing polymers that fix scratches using light rather than heat have been developed by a team of researchers in the United States and Switzerland.

These “metallo-supramolecular polymers” are capable of becoming a supple liquid that fills crevasses and gaps left by scrapes and scuffs when placed under ultraviolet light for less than a minute and then resolidifying.

The new materials were created by a mechanism known as supramolecular assembly. Unlike conventional polymers, which consist of long, chain-like molecules with thousands of atoms, these materials are composed of smaller molecules, which were assembled into longer, polymer-like chains using metal ions as “molecular glue” to create the metallo-supramolecular polymers.

The metallo-supramolecular polymers behave in many ways like normal polymers: when irradiated with intense ultraviolet light the assembled structures become temporarily unglued. This transforms the originally solid material into a liquid that flows easily. When the light is switched off, the material re-assembles and solidifies again and its original properties are restored.

Using lamps such as those dentists use to cure fillings, the researchers repaired scratches in their polymers. Wherever they waved the light beam, the scratches filled up and disappeared.

The scientists envision widespread uses for such re-healable materials in the not-so-distant future, primarily as coatings for consumer goods such as automobiles, floors and furniture.

Ref.: Stuart J. Rowan & Christoph Weder et al., Optically healable supramolecular polymers, Nature, April 21, 2011