Silver nanocubes make super-light-absorbers

December 10, 2012

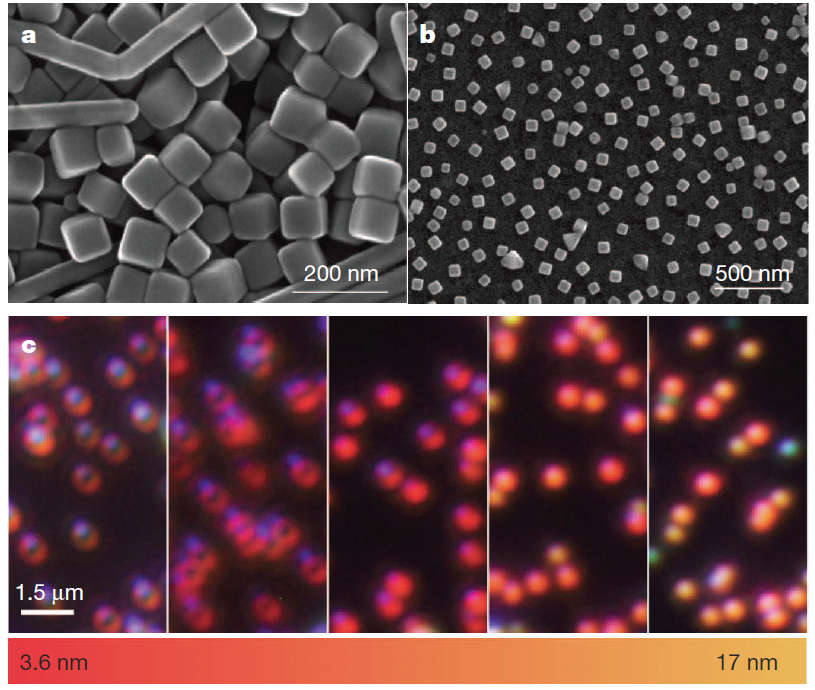

Scanning electronic microscopy images of

silver nanocubes as fabricated (a) and after deposition on the gold film with 17.1% surface coverage and remarkably uniform spacing (b). c, Dark-field images of the nanocubes randomly adsorbed on a nanoscale polymer spacer on a gold film, showing the light scattered by the individual nanocubes for less than

1% surface coverage. (Credit: Cristian Ciraci)

Microscopic metallic cubes could unleash the enormous potential of metamaterials to absorb light, leading to more efficient and cost-effective large-area absorbers for sensors or solar cells, Duke University researchers have found.

Metamaterials are man-made materials that have properties often absent in natural materials. They are constructed to provide exquisite control over the properties of waves, such as light.

Creating these materials for visible light is still a technological challenge that has traditionally been achieved by lithography, in which metallic patterns are etched onto an inert material, much like an ink-jet printer.

However, lithography is very expensive, making it difficult to scale up to the large surface areas required for many applications.

“Our new approach is more of a bottom-up process,” said Cristian Ciracì, research scientist at Duke’s Pratt School of Engineering. “It may allow us to create devices — such as efficient solar panels — that cover much larger areas. In our experiments, we demonstrated an extraordinarily simple method to achieve this.”

For many applications or devices, the key is the material’s ability to control the absorption of electromagnetic waves. Metals, for example, can be highly reflective on their own, which may be beneficial for some applications, but for something like a solar cell, optimal light absorption is desired.

“However, metamaterials based on metallic elements are particularly efficient as absorbers because both the electrical and magnetic properties of the material can be controlled by how we design them,” Ciracì said.

The new metamaterial developed by the Duke team has three major components — a thin layer of gold film coated with a nano-thin layer of an insulator, topped off with a dusting of millions of self-assembled nanocubes. In the current experiments, the nanocubes were fabricated out of silver.

“The nanocubes are literally scattered on the gold film and we can control the properties of the material by varying the geometry of the construct,” Ciracì said. “The absorptivity of large surface areas can now be controlled using this method at scales out of reach of lithography.”

While metals on their own tend to have reflective properties, the nanocubes act as tiny antennae that can cancel out the reflectance of the metal surface.

“By combining different components of the metamaterial elements together into a single composite, more complicated reflectance spectra could be engineered, achieving a level of control needed in more exotic applications, such as dynamic inks,” Ciracì said.

The research was supported by the Air Force Office of Scientific Research and by the Army Research Office’s Multidisciplinary University Research Initiative (MURI).