Student engineers design, build, fly ‘printed’ airplane

October 23, 2012

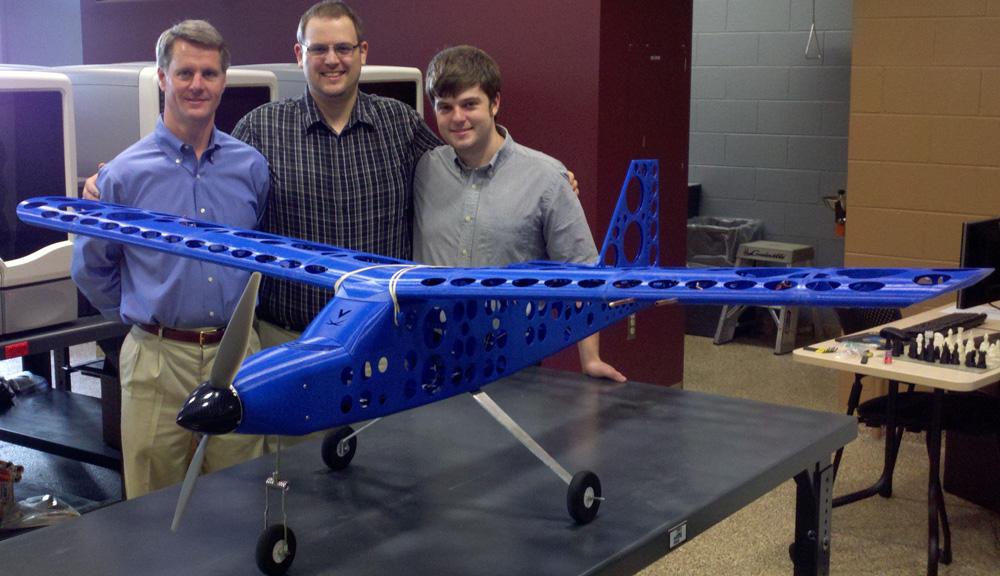

The unmanned aerial vehicle, “dressed” in U.Va.’s colors. The plane was built entirely from parts from a 3-D printer. (Credit: University of Virginia)

The MITRE Corporation hired two University of Virginia engineeering students to build an unmanned aerial vehicle, using 3D printing technology, part of a Department of the Army project to study the feasibility of using such planes.

The result was a plane with a 6.5-foot wingspan, made from assembled “printed” parts. It achieved a cruising speed of 45 mph and is only the third 3D-printed plane known to have been built and flown.

“To make a plastic turbofan engine to scale five years ago would have taken two years, at a cost of about $250,000,” the students said. “But with 3D printing we designed and built it in four months for about $2,000. This opens up an arena of teaching that was not available before. It allows us to train engineers for the real challenges they will face in industry.”