‘Terminator’ polymer regenerates itself

September 16, 2013

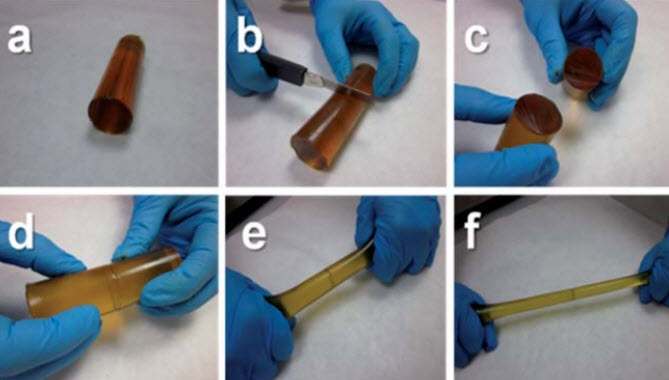

A cylindrical sample of a polymer (a) was cut in half (b and c) and the two halves were then allowed to stand for 2 hours by simple contact (d). After that time, the material could be manually stretched without rupture (e and f). (credit: Royal Society of Chemistry)

Scientists have developed the first self-healing polymer that can spontaneously achieve healing in the absence of a catalyst.

Self-healing polymers have been able to mend themselves by reforming broken cross-linking bonds, but that requires an external catalyst (trigger) to promote bond repair, such as heat, light, or specific environmental conditions, such as pH.

Ibon Odriozola at the CIDETEC Centre for Electrochemical Technologies in Spain used a poly(urea–urethane) elastomeric network, which completely mended itself after being cut in two by a razor blade. It is the metathesis reaction of aromatic disulphided (which naturally exchange at room temperature) that causes regeneration.

T-1000 terminator (credit: TriStar Pictures)

The ‘terminator’ polymer

Ibon says the polymer behaves as if it was alive, always healing itself and has dubbed it a “terminator” polymer — a tribute to the shape-shifting, molten T-1000 terminator robot from the Terminator 2 film.

It acts as a velcro-like sealant or adhesive, displaying an impressive 97% healing efficiency in just two hours, and does not break when stretched manually.

David Mecerreyes, a polymer chemistry specialist at the University of the Basque Country in Spain, sees opportunities to use this elastomer to improve the security and duration of many plastic parts, for example in cars, houses, electrical components and biomaterials.

Future work by the group will concentrate on stronger polymeric materials; the current poly(urea–urethane) composite is relatively soft.

Source: Royal Society of Chemistry