Thinnest-possible nanomembrane produced

April 18, 2014

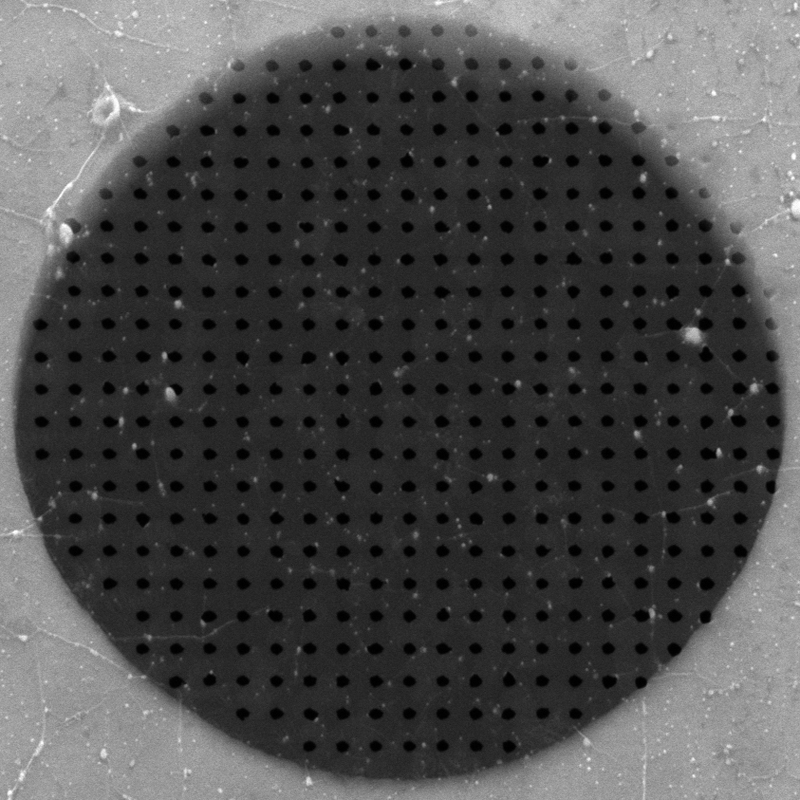

Part of a graphene membrane with a multiplicity of pores (black) of precisely defined size (credit: Celebi K. et al. /Science)

ETH Zurich, Empa, LG Electronics researchers have created the thinnest-possible nanomembrane. Made out of graphene, it is extremely light and breathable, and could lead to a new generation of functional waterproof clothing and ultra-rapid filtration.

The stable porous membrane consists of two layers of graphene, a two-dimensional film made of carbon atoms, on which the researchers etched tiny pores of a precisely defined size to allow for selective filtration by molecular size.

The study has been published in the journal Science.

“Our membrane is not only very light and flexible, but it is also a thousand fold more breathable than Goretex,” says Kemal Celebi, a postdoc in the lab of Professor Hyung Gyu Park at the Department of Mechanical and Process Engineering at ETH Zurich and one of the lead authors of the study.

Filtering water and gaseous mixtures

The membrane could also potentially be used to separate gaseous mixtures into their constituent parts or to filter impurities from fluids. The researchers were able to demonstrate for the first time that graphene membranes could be suitable for water filtration. The researchers also see a potential use for the membrane in devices used for the accurate measurement of gas and fluid flow rates, which are crucial to unveiling the physics around mass transfer at nanoscale and separation of chemical mixtures.

The researchers used a technique called focused ion beam milling to etch pores into the graphene film. In this process, which is also used in the production of semiconductors, a beam of helium or gallium ions is controlled with a high level of precision in order to etch away material. The researchers were able to etch pores of a specified number and size into the graphene with unprecedented precision. This process, which could easily take days to complete, took only a few hours in the current work.

“This is a breakthrough that enables the nanofabrication of the porous graphene membranes,” explains Ivan Shorubalko, a scientist at Empa that also contributed to the study.

To achieve this level of precision, the researchers had to work with double-layer graphene. “It wouldn’t have been possible for this method to create such a membrane with only one layer because graphene in practice isn’t perfect,” says Park. The material can exhibit certain irregularities in the honeycomb structure of the carbon atoms. Individual atoms are sometimes missing from the structure, which not only impairs the stability of the material but also makes it impossible to etch a high-precision pore onto such a defect. The researchers solved this problem by laying two graphene layers on top of each other. The probability of two defects settling directly above one another is extremely low, explains Park.

Fastest possible filtration

A key advantage of the tiny dimensions is that the thinner a membrane, the lower its permeation resistance. The lower the resistance, the higher the energy-efficiency of the filtration process. “With such atomically thin membranes we can reach maximal permeation for a membrane of a given pore size and we believe that they allow the fastest feasible rate of permeation,” says Celebi.

However, before these applications are ready for use on an industrial scale or for the production of functional waterproof clothing, the manufacturing process needs to be further developed. To investigate the fundamental science, the researchers worked with tiny pieces of membrane with a surface area of less than one hundredth of a square millimeter. Objectives from now on will be to produce larger membrane surfaces and impose various filtering mechanisms.

Abstract of Science paper

A two-dimensional (2D) porous layer can make an ideal membrane for separation of chemical mixtures because its infinitesimal thickness promises ultimate permeation. Graphene—with great mechanical strength, chemical stability, and inherent impermeability—offers a unique 2D system with which to realize this membrane and study the mass transport, if perforated precisely. We report highly efficient mass transfer across physically perforated double-layer graphene, having up to a few million pores with narrowly distributed diameters between less than 10 nanometers and 1 micrometer. The measured transport rates are in agreement with predictions of 2D transport theories. Attributed to its atomic thicknesses, these porous graphene membranes show permeances of gas, liquid, and water vapor far in excess of those shown by finite-thickness membranes, highlighting the ultimate permeation these 2D membranes can provide.