Ultra-thin capacitors could acclerate development of next-gen electronics

February 28, 2014

Japanese researchers at the National Institute for Materials Science and Shinshu University have developed a way to shrink capacitors — key components that store energy — further, which could accelerate the development of more compact, high-performance next-gen electronic devices. The study appears in the journal ACS Nano.

Takayoshi Sasaki and colleagues note that current technology has almost reached its limit in terms of materials and processing, which in turn limits the performance that manufacturers can achieve. In response, researchers have gone to the nanoscale, but “nanocapacitors” are not easy to make. They require harsh, difficult-to-use methods and even then, they may not work that well.

Layers of different types of oxide nanosheets

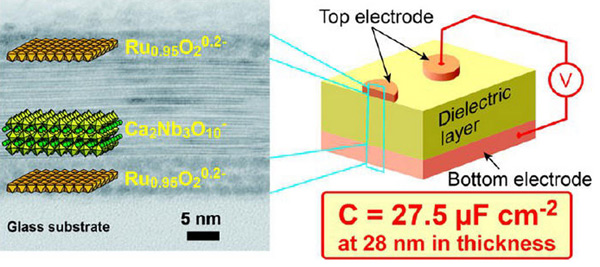

So Sasaki’s team developed an easier way to make high-performance “ultrathin” capacitors. The researchers found that they could use gentle techniques and mild conditions to create a sandwich consisting of layers of two different types of oxide nanosheets to produce an ultrathin capacitor.

In addition, the new capacitor has a capacitance density of as high as ∼27.5 μF (microfarads) per square centimeter, which is approximately 2000 times higher than those of currently available commercial products.

The fabrication process, involving layer-by-layer assembly of the nanosheets without costly fabrication lines and special annealing processes for metal electrode layers is another big benefit. Furthermore, the all-nanosheet capacitors can be readily assembled on plastic or flexible substrates.

Better than graphene

The researchers say that, in the future, the ultrathin capacitors could be used in printed circuit boards and in DRAM memory storage devices, for example. They also speculate that “the virtually infinite varieties of oxide nanosheets, which can be used to assemble various nanosheet architectures, suggest that 2D heterointerfaces will offer an unprecedented versatility for the realization of new 2D states and molecularly thin film devices even beyond graphene.”

The authors acknowledge funding from the Japan Science and Technology Agency and MEXT, Japan.

Abstract of ACS Nano paper

All-nanosheet ultrathin capacitors of Ru0.95O20.2–/Ca2Nb3O10–/Ru0.95O20.2– were successfully assembled through facile room-temperature solution-based processes. As a bottom electrode, conductive Ru0.95O20.2– nanosheets were first assembled on a quartz glass substrate through a sequential adsorption process with polycations. On top of the Ru0.95O20.2– nanosheet film, Ca2Nb3O10– nanosheets were deposited by the Langmuir–Blodgett technique to serve as a dielectric layer. Deposition parameters were optimized for each process to construct a densely packed multilayer structure. The multilayer buildup process was monitored by various characterizations such as atomic force microscopy (AFM), ultraviolet–visible absorption spectra, and X-ray diffraction data, which provided compelling evidence for regular growth of Ru0.95O20.2– and Ca2Nb3O10– nanosheet films with the designed multilayer structures. Finally, an array of circular films (50 μm  ) of Ru0.95O20.2– nanosheets was fabricated as top electrodes on the as-deposited nanosheet films by combining the standard photolithography and sequential adsorption processes. Microscopic observations by AFM and cross-sectional transmission electron microscopy, as well as nanoscopic elemental analysis, visualized the sandwich metal–insulator–metal structure of Ru0.95O20.2–/Ca2Nb3O10–/Ru0.95O20.2– with a total thickness less than 30 nm. Electrical measurements indicate that the system really works as an ultrathin capacitor, achieving a capacitance density of

) of Ru0.95O20.2– nanosheets was fabricated as top electrodes on the as-deposited nanosheet films by combining the standard photolithography and sequential adsorption processes. Microscopic observations by AFM and cross-sectional transmission electron microscopy, as well as nanoscopic elemental analysis, visualized the sandwich metal–insulator–metal structure of Ru0.95O20.2–/Ca2Nb3O10–/Ru0.95O20.2– with a total thickness less than 30 nm. Electrical measurements indicate that the system really works as an ultrathin capacitor, achieving a capacitance density of  27.5 μF cm–2, which is far superior to currently available commercial capacitor devices. This work demonstrates the great potential of functional oxide nanosheets as components for nanoelectronics, thus contributing to the development of next-generation high-performance electronic devices.

27.5 μF cm–2, which is far superior to currently available commercial capacitor devices. This work demonstrates the great potential of functional oxide nanosheets as components for nanoelectronics, thus contributing to the development of next-generation high-performance electronic devices.