Unusual 3D nanostructure could benefit nanoelectronics, gas storage

July 18, 2014

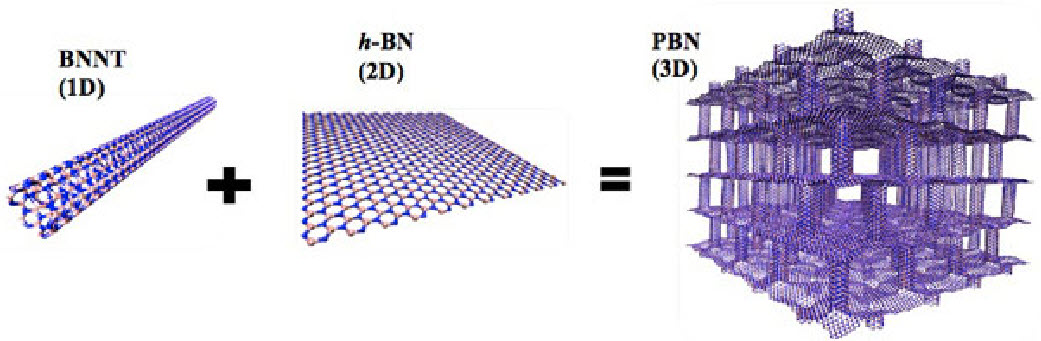

Boron nitride 1D nanotubes combined with 2D graphene-like form create 3D boron nitride (credit: Rice University)

An unusual three-dimensional porous nanostructure called pillared boron nitride (PBN) could achieve a balance of strength, toughness, and ability to transfer heat that could benefit nanoelectronics, gas storage, and composite materials that perform multiple functions, Rice University engineers have discovered.

Their findings were published online July 14 in the Journal of Physical Chemistry C.

The 3-D prototypes they made (using computer simulations) fuse one-dimensional boron nitride nanotubes and two-dimensional sheets of boron nitride. The extremely thin sheets of boron nitride are stacked in parallel layers, with tube-shaped pillars of boron nitride between each layer to keep the sheets separated.

Among 3-D boron nitride’s unusual properties:

- Can be stretched about 45 percent of its length without breaking in the direction of the columns.

- Carries heat relatively fast in all 3-D directions. “This feature is ideal for applications that require materials or coating with the capability of extremely fast thermal diffusion to the environments,” said Rouzbeh Shahsavari, assistant professor of civil and environmental engineering and of materials science and nanoengineering. “Examples include car engines or computer CPUs where a fast heat transfer to the environments is critical in proper functioning.”

- Has a very porous and lightweight structure. Each gram of this Swiss cheese-like structure has a surface area equivalent to three tennis courts. Such a high surface area lends itself to customized applications, such as efficient gas storage and separation — in vehicles that run on hydrogen cells, for example.

- Is an electrically insulating material, so it could complement electrically conductive graphene-based nanoelectronics — for example, in the next generation of 3-D semiconductors and 3-D thermal transport devices, which could be used in nanoscale calorimeters, microelectronic processes, and macroscopic refrigerators.

The actual 3-D boron nitride prototype material still has to be created in the lab, and numerous efforts are already underway. “Our computer simulations show what properties can be expected from these structures and what the key factors are that control their functionality,” Shahsavari said.

The research was funded by Rice University.

Abstract of The Journal of Physical Chemistry C paper

One-dimensional (1D) Boron Nitride nanotube (BNNT) and 2D hexagonal BN (h-BN) are attractive for demonstrating fundamental physics and promising applications in nano/microscale devices. However, there is a high anisotropy associated with these BN allotropes as their excellent properties are either along the tube axis or in-plane directions, posing an obstacle in their widespread use in technological and industrial applications. Herein, we report a series of 3D BN prototypes, namely Pillared Boron Nitride (PBN), by fusing single wall BNNT and monolayer h-BN aimed at filling this gap. We use density functional theory and molecular dynamics simulations to probe the diverse mechano-mutable properties of PBN prototypes. Our results demonstrate that the synergistic effect of the tubes, junctions, and sheets imparts cooperative deformation mechanisms, which overcome the intrinsic limitations of the PBN constituents and provide a number of superior characteristics including 3D balance of strength and toughness, emergence of negative Poisson’s ratio, and elimination of strain softening along the armchair orientation. These features, combined with the ultrahigh surface area and lightweight structure, render PBN as a 3D multifunctional template for applications in graphene-based nanoelectronics, optoelectronics, gas storage and functional composites with fascinating in-plane and out-of-plane tailorable properties.