Water splitter produces clean-burning hydrogen fuel 24/7

June 23, 2015

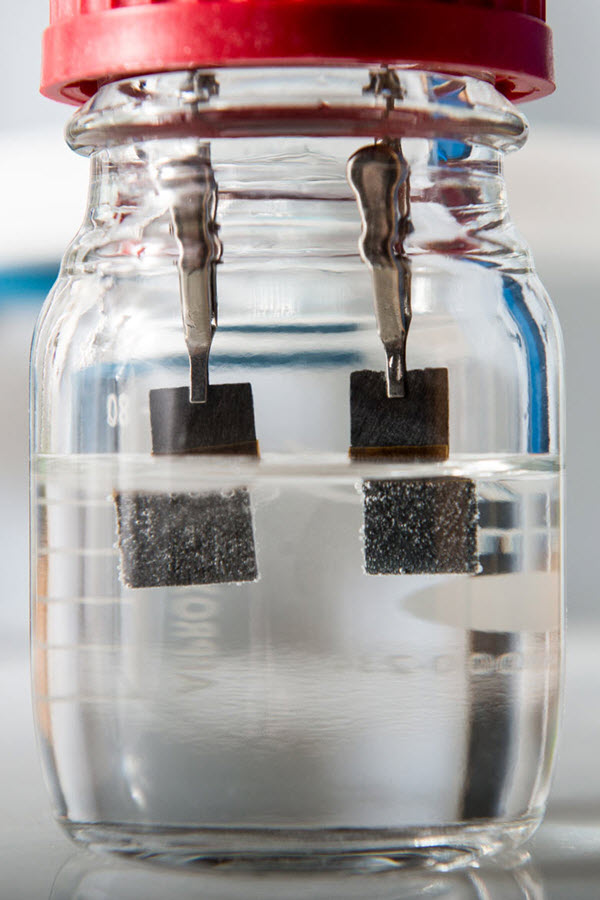

Unlike conventional water splitters, the Stanford device uses a single low-cost catalyst to generate hydrogen on one electrode and oxygen on the other (credit: L.A. Cicero/Stanford University)

In an engineering first, Stanford University scientists have invented a low-cost water splitter that uses a single catalyst to produce both hydrogen and oxygen gas 24 hours a day, seven days a week.

The researchers believe that the device, described in an open-access study published today (June 23) in Nature Communications, could provide a renewable source of clean-burning hydrogen fuel for transportation and industry.

“We have developed a low-voltage, single-catalyst water splitter that continuously generates hydrogen and oxygen for more than 200 hours, an exciting world-record performance,” said study co-author Yi Cui, an associate professor of materials science and engineering at Stanford and of photon science at the SLAC National Accelerator Laboratory.

The search for clean hydrogen

Hydrogen has long been promoted as an emissions-free alternative to gasoline. But most commercial-grade hydrogen is made from natural gas — a fossil fuel that contributes to global warming. So scientists have been trying to develop a cheap and efficient way to extract pure hydrogen from water.

A conventional water-splitting device consists of two electrodes submerged in a water-based electrolyte. A low-voltage current applied to the electrodes drives a catalytic reaction that separates molecules of H2O, releasing bubbles of hydrogen on one electrode and oxygen on the other.

In these devices, each electrode is embedded with a different catalyst, typically platinum and iridium, two rare and costly metals. But in 2014, Stanford chemist Hongjie Dai developed a water splitter made of inexpensive nickel and iron that runs on an ordinary 1.5-volt battery.

In the new study, Cui and his colleagues advanced that technology further.

Stanford University | Stanford water splitter produces clean hydrogen 24/7

A single catalyst

In conventional water splitters, the hydrogen and oxygen catalysts often require different electrolytes with different pH — one acidic, one alkaline — to remain stable and active. “For practical water splitting, an expensive barrier is needed to separate the two electrolytes, adding to the cost of the device,” Wang explained.

“Our water splitter is unique because we only use one catalyst, nickel-iron oxide, for both electrodes,” said graduate student Haotian Wang, lead author of the study. “This bi-functional catalyst can split water continuously for more than a week with a steady input of just 1.5 volts of electricity. That’s an unprecedented water-splitting efficiency of 82 percent at room temperature.”

Wang and his colleagues discovered that nickel-iron oxide, which is cheap and easy to produce, is actually more stable than some commercial catalysts made of expensive precious metals.

The key to making a single catalyst possible was to use lithium ions to chemically break the metal oxide catalyst into smaller and smaller pieces. That “increases its surface area and exposes lots of ultra-small, interconnected grain boundaries that become active sites for the water-splitting catalytic reaction,” Cui said. “This process creates tiny particles that are strongly connected, so the catalyst has very good electrical conductivity and stability.”

Lower cost

Using one catalyst made of nickel and iron also has significant implications in terms of cost.

“Not only are the materials cheaper, but having a single catalyst also reduces two sets of capital investment to one,” Cui said. “We believe that electrochemical tuning can be used to find new catalysts for other chemical fuels beyond hydrogen. The technique has been used in battery research for many years, but it’s a new approach for catalysis. The marriage of these two fields is very powerful. ”

“Our group has pioneered the idea of using lithium-ion batteries to search for catalysts,” Cui said. “Our hope is that this technique will lead to the discovery of new catalysts for other reactions beyond water splitting.”

Support was provided by the Global Climate and Energy Project at Stanford and the Stanford Interdisciplinary Graduate Fellowship program.

Abstract of Bifunctional non-noble metal oxide nanoparticle electrocatalysts through lithium-induced conversion for overall water splitting

Developing earth-abundant, active and stable electrocatalysts which operate in the same electrolyte for water splitting, including oxygen evolution reaction and hydrogen evolution reaction, is important for many renewable energy conversion processes. Here we demonstrate the improvement of catalytic activity when transition metal oxide (iron, cobalt, nickel oxides and their mixed oxides) nanoparticles (~20 nm) are electrochemically transformed into ultra-small diameter (2–5 nm) nanoparticles through lithium-induced conversion reactions. Different from most traditional chemical syntheses, this method maintains excellent electrical interconnection among nanoparticles and results in large surface areas and many catalytically active sites. We demonstrate that lithium-induced ultra-small NiFeOx nanoparticles are active bifunctional catalysts exhibiting high activity and stability for overall water splitting in base. We achieve 10 mA cm−2 water-splitting current at only 1.51 V for over 200 h without degradation in a two-electrode configuration and 1 M KOH, better than the combination of iridium and platinum as benchmark catalysts.