World’s smallest semiconductor laser

July 30, 2012

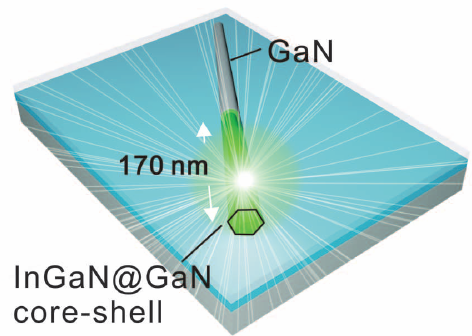

Illustration of the nanoscale semiconductor structure used for demonstrating the ultra-low-threshold nanolaser. A single nanorod is placed on a thin (28 nm) silver film. The resonant electromagnetic field is concentrated at the 5-nm-thick silicon dioxide gap layer sandwiched by the semiconductor nanorod and the atomically smooth silver film. (Credit: University of Texas at Austin/Science)

Physicists at The University of Texas at Austin and colleagues in Taiwan and China have developed the world’s smallest semiconductor laser, a breakthrough for emerging photonic technology with applications from computing to medicine.

Miniaturization of semiconductor lasers is key for the development of faster, smaller and lower energy photon-based technologies, such as ultrafast computer chips, next-generation communication technologies, and highly sensitive biosensors for detecting, treating and studying disease.

Such photonic devices could use nanolasers to generate optical signals and transmit information, and they have the potential to replace electronic circuits. But the size and performance of photonic devices have been restricted by the three-dimensional optical diffraction limit (based on the wavelength of light and refractive index of the dielectric material).

“We have developed a nanolaser device that operates well below the 3-D diffraction limit,” said Chih-Kang “Ken” Shih, professor of physics at The University of Texas at Austin. “We believe our research could have a large impact on nanoscale technologies.”

Shih and his colleagues report the first operation of a continuous-wave, low-threshold laser below the 3D diffraction limit. When fired, the nanolaser emits a green light. The laser is too small to be visible to the naked eye.

Atomic smoothness

The device is constructed of a gallium nitride nanorod that is partially filled with indium gallium nitride. Both alloys are semiconductors used commonly in LEDs. The nanorod is placed on top of a thin insulating layer of silicon that in turn covers a layer of silver film that is smooth at the atomic level.

It’s a material that the Shih lab has been perfecting for more than 15 years. That “atomic smoothness” is key to building photonic devices that don’t scatter and lose plasmons, which are waves of electrons that can be used to move large amounts of data. (An analogy is the limit to how fast a car can travel on a bumpy road.)

“Atomically smooth plasmonic structures are highly desirable building blocks for applications with low loss of data,” said Shih.

Nanolasers such as this could provide for the development of chips where all processes are contained on the chip, in “on-chip” communication systems. This would prevent the heat gains and information loss typically associated with electronic devices that pass data between multiple chips.

“Size mismatches between electronics and photonics have been a huge barrier to realize on-chip optical communications and computing systems,” said Shangjr Gwo, professor at National Tsing Hua University in Taiwan.