Would you eat ‘eco-friendly’ meat created from stem cells?

May 23, 2014

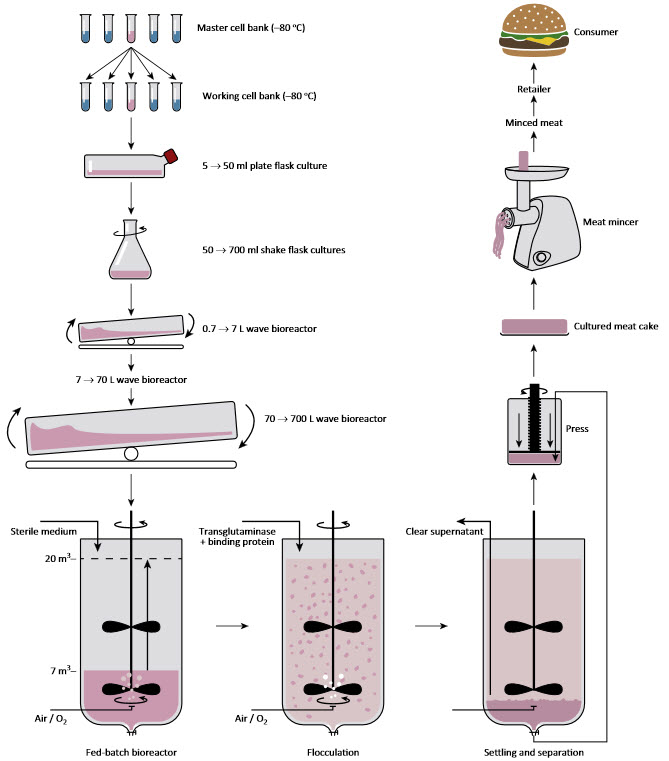

Flow chart of a potential cultured-meat manufacturing process. The left column shows the stepwise increase in cell-culture volume, starting with a vial from the working cell bank (note that a new working cell bank is made from a vial from the master cell bank). After growing to a certain cell density, exponentially growing cells from each step serve as the inoculum of the next culture vessel, which is an order of magnitude larger. The final bioreactor starts only partially filled and is fed with sterile medium at such a rate that the cells grow further under optimal conditions. When the bioreactor is full and the desired cell density is reached, the protein-crosslinking enzyme transglutaminase and binding protein are added to induce the formation of easily settling aggregates of cells, which quickly settle when stirring is stopped (bottom right). The harvested cells are pressed and the cake is extruded into retailer- and/or consumer-size portions of minced meat (right column). (Credit: Trends in Biotechnology, van der Weele et al.)

In a paper in the Cell Press journal Trends in Biotechnology, Cor van der Weele of Wageningen University in The Netherlands and coauthor Johannes Tramper describe a potential meat manufacturing process, starting with a vial of cells taken from a cell bank and ending with a pressed cake of minced meat.

Cor van der Weele point out that the rising demand for meat around the world is unsustainable in terms of environmental pollution and energy consumption, in addition to animal suffering associated with factory farming.

Fortunately, it’s already possible to make meat from stem cells, as demonstrated by Mark Post, a professor of tissue engineering at Maastricht University who created the first lab-grown hamburger in 2013.

There will be challenges when it comes to maintaining a continuous stem cell line and producing cultured meat that’s cheaper than meat obtained in the usual way, they say.

However, “cultured meat has great moral promise,” write van der Weele and Tramper. “Worries about its unnaturalness might be met through small-scale production methods that allow close contact with cell-donor animals, thereby reversing feelings of alienation. From a technological perspective, ‘village-scale’ production is also a promising option.”

Dutch scientists suggest that every town or village could one day have its own small-scale, cultured meat factory based on stem cells. “We believe that cultured meat is part of the future,” said van der Weele.

Abstract of Trends in Biotechnology paper

Rising global demand for meat will result in increased environmental pollution, energy consumption, and animal suffering. Cultured meat, produced in an animal-cell cultivation process, is a technically feasible alternative lacking these disadvantages, provided that an animal-component-free growth medium can be developed. Small-scale production looks particularly promising, not only technologically but also for societal acceptance. Economic feasibility, however, emerges as the real obstacle.