A high-performance microbattery that can be built into chips

May 13, 2015

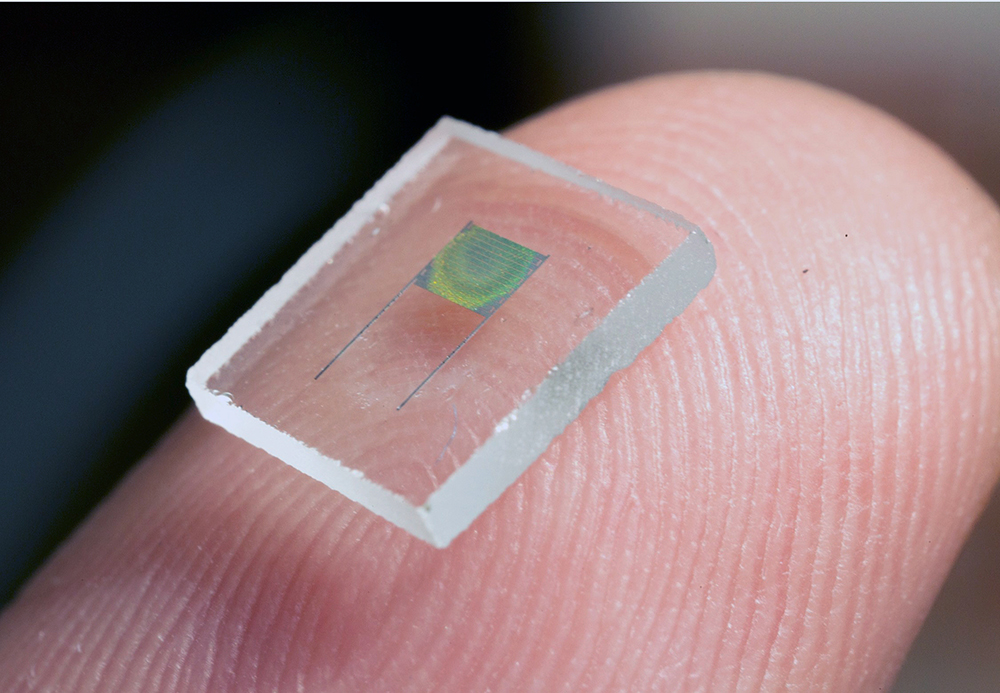

A high-performance 3D microbattery that could be integrated into microchips at production volumes has been developed by University of Illinois at Urbana-Champaign researchers.

Miniaturizing a battery to fit in a microchip is a major challenge, but it would be important for providing power to microscale devices such as actuators, distributed wireless sensors and transmitters, and portable and implantable medical devices, explained Paul Braun, a professor of materials science and engineering (MatSE) at Illinois and lead author of a paper on the research in Proceedings of the National Academy of Sciences.

“Micro-scale devices typically utilize power supplied off-chip because of difficulties in miniaturizing energy storage technologies,” he pointed out.

The breakthrough was based on combining two state-of-the-art technologies. They used 3D holographic lithography and and 2D photolithography to create well-defined, periodically structured porous electrodes, allowing for fast movement of electrons and ions inside the battery for high energy density and high power density.

The research is supported by the U.S. Department of Energy, Office of Basic Energy Sciences, Division of Materials Sciences and Engineering.

Abstract of Holographic patterning of high-performance on-chip 3D lithium-ion microbatteries

As sensors, wireless communication devices, personal health monitoring systems, and autonomous microelectromechanical systems (MEMS) become distributed and smaller, there is an increasing demand for miniaturized integrated power sources. Although thin-film batteries are well-suited for on-chip integration, their energy and power per unit area are limited. Three-dimensional electrode designs have potential to offer much greater power and energy per unit area; however, efforts to date to realize 3D microbatteries have led to prototypes with solid electrodes (and therefore low power) or mesostructured electrodes not compatible with manufacturing or on-chip integration. Here, we demonstrate an on-chip compatible method to fabricate high energy density (6.5 μWh cm−2⋅μm−1) 3D mesostructured Li-ion microbatteries based on LiMnO2 cathodes, and NiSn anodes that possess supercapacitor-like power (3,600 μW cm−2⋅μm−1 peak). The mesostructured electrodes are fabricated by combining 3D holographic lithography with conventional photolithography, enabling deterministic control of both the internal electrode mesostructure and the spatial distribution of the electrodes on the substrate. The resultant full cells exhibit impressive performances, for example a conventional light-emitting diode (LED) is driven with a 500-μA peak current (600-C discharge) from a 10-μm-thick microbattery with an area of 4 mm2 for 200 cycles with only 12% capacity fade. A combined experimental and modeling study where the structural parameters of the battery are modulated illustrates the unique design flexibility enabled by 3D holographic lithography and provides guidance for optimization for a given application.