A new low-cost way to create 3D nanostructures

December 9, 2014

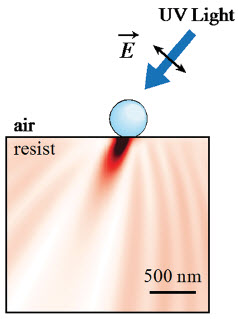

Nanospheres used to create 3D nanopatterns (credit: Xu Zhang)

Researchers from North Carolina State University (NC State) have developed a new low-cost lithography technique that can create three-dimensional (3D) nanostructures for biomedical, electronic, and photonic applications, replacing laborious stacking of two-dimensional (2D) patterns to create 3D structures.

“Our approach reduces the cost of nanolithography to the point where it could be done in your garage,” says Dr. Chih-Hao Chang, an assistant professor of mechanical and aerospace engineering at NC State and senior author of a paper on the work.

Most conventional lithography uses a variety of techniques to focus light on a photosensitive film to create 2D patterns. These techniques rely on specialized lenses, electron beams or lasers — all of which are extremely expensive. Other conventional techniques use mechanical probes, which are also costly.

To create 3D structures, the 2D patterns are essentially printed on top of each other.

The NC State researchers took a different approach, using nanoscale polystyrene spheres. The nanospheres are transparent, but bend and scatter the light that passes through them in predictable ways, according to the angle that the light takes when it hits the nanosphere.

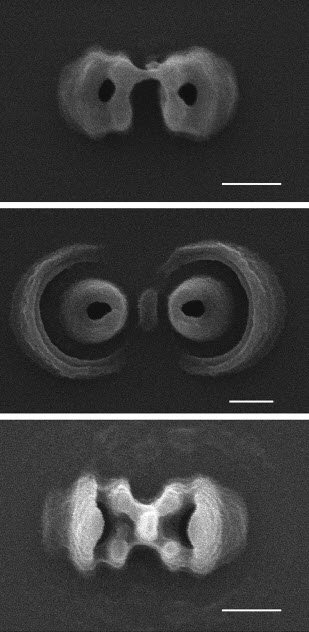

A variety of hollow-core 3D nanostructures (scale bars: 500 nanometers) (credit: Xu Zhang)

The researchers control the nanolithography (printing ultraminiature patterns) by altering the size of the nanosphere, the duration of light exposures, and the angle, wavelength and polarization of light. The researchers can also use one or multiple beams of light, allowing them to create a wide variety of nanostructure designs.

“We are using the nanosphere to shape the pattern of light, which gives us the ability to shape the resulting nanostructure in three dimensions without using the expensive equipment required by conventional techniques,” Chang says. “And it allows us to create 3D structures all at once, without having to make layer after layer of 2D patterns.”

The researchers have also shown that they can get the nanospheres to self-assemble in a regularly-spaced array, which in turn can be used to create a uniform pattern of 3D nanostructures.

The slanted hollow structures can be fabricated in an ordered periodic array, which can find applications in nanoneedles for medical nanomaterial drug delivery, nanoscale “inkjet printers” for printing electronics or biological cells, antennas, or photonic components.

The work was published online Dec. 8 in the journal Small and supported by a NASA Early Career Faculty grant and by the Nanosystems Engineering Research Center for Advanced Self-Powered Systems of Integrated Sensors and Technologies at NC State, under a National Science Foundation grant.

Abstract of Sculpting Asymmetric, Hollow-Core, Three-Dimensional Nanostructures Using Colloidal Particles

Colloidal elements have historically played a key role in “bottom-up” self-assembly processes for nanofabrication. However, these elementary components can also interact with light to generate complex intensity distributions and facilitate “top-down” lithography. Here, a nanolithography technique is demonstrated based on oblique illuminations of colloidal particles to fabricate hollow-core 3D nanostructures with complex symmetry. The light–particle interaction generates an angular light distribution as governed by Mie scattering, which can be compounded by multiple illuminations to sculpt novel 3D structures in the underlying photoresist. The fabricated geometry can be controlled by the particle parameters and illumination configurations, enabling the fabrication of a large variety of asymmetric hollow nanostructures. The proposed technique has high pattern versatility, is low cost and high throughput, and can find potential application in nanoneedles, nanonozzles, and materials with anisotropic properties.