Custom-made ultrathin carbon nanomembranes

August 26, 2013

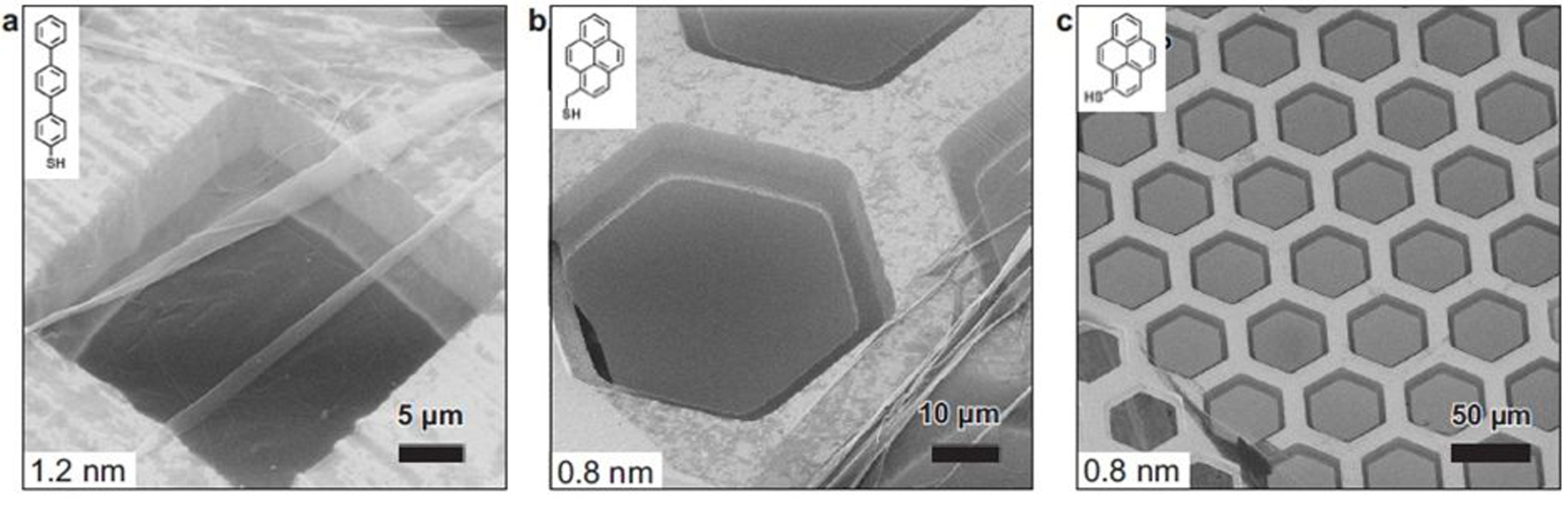

Nanomembranes made from various starting materials (credit: Bielefeld University)

Bielefeld University researchers have developed a new way to produce a variety of carbon nanomembranes (CNM) from self-assembled monolayers (SAMs). The CNMs consist of just one layer of molecules, with a thickness of ∼0.5 to ∼3 nm. — much thinner than conventional membranes

In the future, CNMs are expected to be able to filter out very fine materials and allow for separating gases from one another — for example, filtering toxins from the air.

How to make nanomembranes

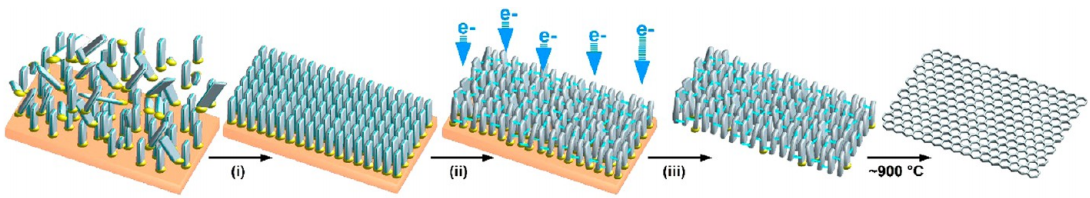

Schematic for the formation of carbon nanomembranes (CNMs) and graphene from molecular precursors. Self-assembled monolayers are prepared on a substrate (i), then cross-linked by electron irradiation to form CNMs of monomolecular thickness (ii). The CNMs are released from the underlying substrate (iii), and further annealing at 900 C transforms them into graphene. (Credit: Polina Angelova/ACS Nano)

1. Dissolve the starting material is powder form in pure alcohol.

2. Immerse a very thin metal layer in this solution. After a short time the dissolved molecules settle themselves on the metal layer to form a monolayer of molecules.

3. Expose to electron irradiation, causing the monolayer to become a cross-linked nanomembrane. Ensure that the metal layer disintegrates, leaving only the nanomembrane remaining.

This new method allows for producing made-to-measure nanomembranes as big as square meters.

“Every starting material has a different property, from thickness or transparency to elasticity,” said Gölzhäuser. “By using our process, these characteristics are transferred onto the nanomembrane. In this way, carbon nanomembranes can be produced to address many different needs. That was not possible before now.” For example, the process can produce ultrathin films with or without nanopores.

The process also allows for making graphene from nanomembranes by heating them in a vacuum at a temperature of about 700 degrees Celsius.

Gölzhäuser’s team is working on the project with physicists from Ulm University, Frankfurt University, and the Max Planck Institute for Polymer Research.

The study has been funded by the Federal Ministry of Education and Research (BMBF) and the German Research Foundation (DFG).