Dental implants that heal faster and fight infection

September 28, 2013

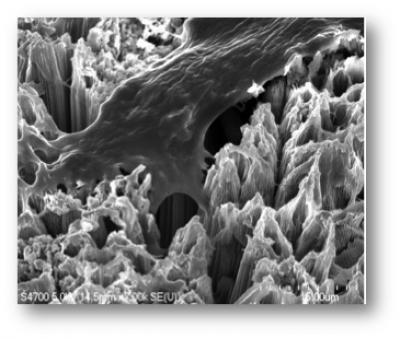

A bone cell anchoring itself to a surface of titanium dioxide nanotubes. Because osteoblasts (cells that synthesize bone tissue).readily adhere to this novel surface, dental implants coated with TiO2 nanotubes could significantly improve healing following dental implant surgery. (Credit: Tolou Shokuhfar/Michigan Technological University)

Michigan Technological University researchers have developed a way to use self-assembled titanium dioxide (TiO2) nanotubes to lower the rate of dental-implant failures.

Dental implants are posts, usually made of titanium, that are surgically placed into the jawbone and topped with artificial teeth.

While most dental implants are successful, a small percentage fail and either fall out or must be removed.

“There are two main issues that concern dentists: infection and separation from the bone,” said Tolou Shokuhfar, an assistant professor of mechanical engineering.

The mouth is a dirty place, so bacterial infections are a risk after implant surgery, and sometimes bone fails to heal securely around the device.

Because jawbones are somewhat thin and delicate, replacing a failed implant can be difficult, not to mention expensive. Generally, dentists charge between $2,000 and $4,000 to install a single implant, and the procedure is rarely covered by insurance.

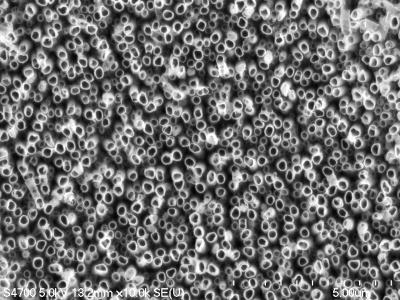

A forest of titanium dioxide nanotubes etched into metallic titanium. The surface may improve the longevity of dental implants. (Credit: Tolou Shokuhfar/Michigan Technological University)

Shokuhfar is now working with Cortino Sukotjo, a clinical assistant professor at the University of Illinois at Chicago (UIC) College of Dentistry on a dental implant with a surface made from TiO2 nanotubes, but she has been making and testing them for several years.

“We have done toxicity tests on the nanotubes, and not only did they not kill cells, they encouraged growth,” she said.

She has already demonstrated that bone cells grow more vigorously and adhere better to titanium coated with TiO2 nanotubes than to conventional titanium surfaces. That could keep more dental implants in place.

Drug delivery

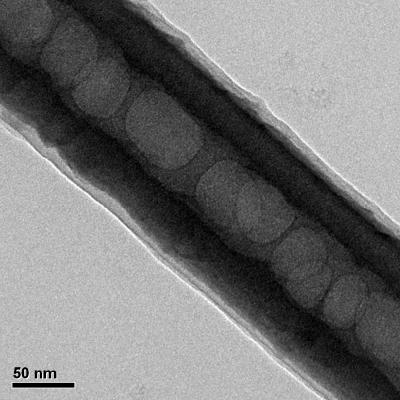

The nanotubes can also be a drug delivery system. Shokuhfar’s team, in collaboration with Alexander Yarin, a professor in UIC’s Department of Mechanical and Industrial Engineering, loaded TiO2 nanotubes with the anti-inflammatory drug sodium naproxen and demonstrated that it could be released gradually after implant surgery.

That assures that the medicine gets where it’s needed, and it reduces the chances of unpleasant side effects that arise when a drug is injected or taken orally.

This cutaway view of a titanium dioxide nanotube reveals the drug sodium naproxen on the inside. On the surface of a dental implant, these nanotubes could release this anti-inflammatory drug or other pharmaceuticals that could speed healing. (Credit: Tolou Shokuhfar/Michigan Technological University)

To fight infection, the TiO2 nanotubes can also be laced with silver nanoparticles. Shokuhfar and Craig Friedrich, who holds the Richard and Bonnie Robbins Chair of Sustainable Design and Manufacturing at Michigan Tech, are conducting research, as yet unpublished, that is focused on orthopedic implants, such as artificial hips, but which also applies to dental implants.

“Silver has antimicrobial properties, and we are capable of obtaining a dose that can kill microbes but would not hurt healthy cells and tissues,” she said. In particular, it can help prevent biofilms, vast colonies of bacteria that can cover implants and be very difficult to eradicate. A nanotextured implant surface embedded with silver nanoparticles could prevent infection for the life of the implant.

The TiO2 nanotubes also have a cosmetic advantage: transparency. That’s a plus for any dental implant, but especially for a new type made from zirconia, which some patients choose because it is totally white.

Shokuhfar expects that implants with the new nanotubular surface will be easily assimilated into the market, since titanium implants, both dental and orthopedic, have a long history.

Shokuhfar and Friedrich have received a provisional patent and are working with two hospitals to further develop the technology and eventually license it. “As soon as the related paper work is taken care of and we get the FDA approval, the technology could be applied. However I am not aware how long all that would take,” she told KurzweilAI.

Interview with Dr. Tolou Shokuhfar (credit: DNN)